Nov . 23, 2024 18:47 Back to list

osy gate valve

Understanding OSY Gate Valves Key Features and Applications

Gate valves are essential components in various industrial applications, providing efficient flow control within piping systems. Among the different types of gate valves, the OSY (Outside Screw and Yoke) gate valve stands out due to its unique design and functionality. This article explores the key features, operational benefits, and applications of OSY gate valves.

Design Characteristics

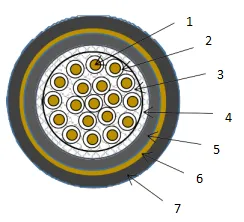

The OSY gate valve is characterized by its distinctive outside screw-and-yoke mechanism. In this design, the valve stem, which operates the gate, is located outside the valve body. This configuration provides several advantages, including ease of operation and maintenance. The yoke, attached to the body of the valve, supports the stem and ensures smooth, linear movement when the valve is opened or closed.

One of the notable features of the OSY gate valve is that its valve position is easily visible from a distance. The threaded stem indicates whether the valve is fully open or closed, enhancing operational safety and efficiency. Additionally, this visibility minimizes the need for manual checks, saving time for operators in busy industrial environments.

Operational Benefits

The OSY gate valve is designed for full flow with minimal pressure drop when fully open. This characteristic makes it a preferred choice for applications requiring swift and efficient fluid transport. Typically, gate valves are used in systems where the flow is either fully on or fully off, making them ideal for isolating sections of a piping network.

osy gate valve

Moreover, the OSY design allows for a significant reduction in the space required for installation. Since the operating stem is external, maintenance tasks, such as replacing seals or lubricating the stem, can be performed without disassembling the entire valve body. This ease of maintenance translates to reduced downtime and lower operational costs for industries relying on continuous fluid flow.

Applications of OSY Gate Valves

OSY gate valves find application across various industries, including water supply, oil and gas, chemical processing, and HVAC systems. In municipal water systems, these valves play a crucial role in isolation and control, allowing operators to manage water flow efficiently. They are also essential in fire protection systems, where reliable operation is critical for safety.

In the oil and gas sector, OSY gate valves are used to manage the flow of crude oil, natural gas, and other hydrocarbons. The robust construction of these valves ensures they can withstand high pressure and harsh operating conditions. The ability to control flow in large diameter pipelines makes them indispensable in this industry.

Another significant application is in power generation. OSY gate valves are often installed in cooling water systems, steam lines, and fuel lines, where their efficient operation ensures optimal energy production. Their reliability and performance are vital for maintaining the operational integrity of power plants.

Conclusion

In summary, OSY gate valves are a crucial element in fluid control systems across various industries. Their unique design, operational efficiency, and ease of maintenance make them an attractive option for engineers and operators alike. Whether managing water supply, oil transport, or steam flow, the OSY gate valve continues to be a reliable choice, adapting to the changing demands of modern industrial applications. Understanding their features and benefits can help professionals make informed decisions regarding the implementation of these essential components in their systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025