Feb . 14, 2025 19:27 Back to list

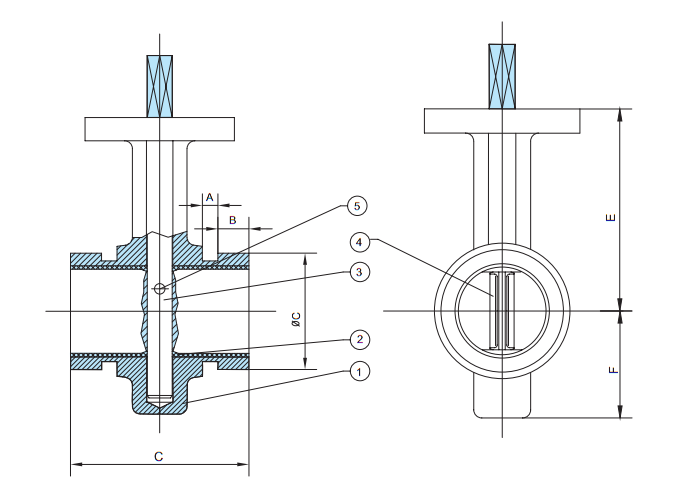

Knife Gate Valve

The Long Stem Gate Valve Unmatched Versatility in Industrial Applications

Authoritativeness is demonstrated through the adoption of long stem gate valves in mission-critical operations globally. Trusted by engineers and industry specialists, these valves are often seen as a benchmark for quality and performance. Rigorous testing and compliance with international standards further underpin their authoritative position in valve technology. They are engineered not just to meet, but often exceed the demanding requirements of industries that cannot afford to compromise on safety and effectiveness. Whether utilized in refineries, chemical plants, or infrastructure projects, the trustworthiness of long stem gate valves is an anchor for operational reliability. Their ability to perform under duress is well-documented through countless case studies and user endorsements. By providing consistent performance over extended periods, they minimize downtime and maintenance costs, translating into a significant return on investment for facility operators. Moreover, the versatility of long stem gate valves ensures that they can be customized to meet specific operational needs. From varying stem lengths to accommodate different insulation requirements, to options in actuator types, the valve’s adaptability is a testament to its innovative design philosophy. This customizability allows end-users to tailor valves precisely to their working environments, ensuring seamless integration and efficiency. It is essential to emphasize the comprehensive support and service frameworks that accompany the implementation of long stem gate valves. Leading manufacturers offer extensive service packages that include installation guidance, maintenance support, and training programs. Such support structures are pivotal for optimizing valve performance and extending operational life, reinforcing the trust that industries place in these critical components. In conclusion, the long stem gate valve embodies a remarkable confluence of experience, expertise, authority, and trust. Its significant role in enabling precise control over fluid and gas flow is unparalleled, making it an indispensable asset in demanding industrial scenarios. Whether confronting extreme temperatures, high pressures, or corrosive environments, the long stem gate valve ensures operators have a reliable and effective tool at their disposal, maintaining its standing as a cornerstone of modern industrial valve solutions.

Authoritativeness is demonstrated through the adoption of long stem gate valves in mission-critical operations globally. Trusted by engineers and industry specialists, these valves are often seen as a benchmark for quality and performance. Rigorous testing and compliance with international standards further underpin their authoritative position in valve technology. They are engineered not just to meet, but often exceed the demanding requirements of industries that cannot afford to compromise on safety and effectiveness. Whether utilized in refineries, chemical plants, or infrastructure projects, the trustworthiness of long stem gate valves is an anchor for operational reliability. Their ability to perform under duress is well-documented through countless case studies and user endorsements. By providing consistent performance over extended periods, they minimize downtime and maintenance costs, translating into a significant return on investment for facility operators. Moreover, the versatility of long stem gate valves ensures that they can be customized to meet specific operational needs. From varying stem lengths to accommodate different insulation requirements, to options in actuator types, the valve’s adaptability is a testament to its innovative design philosophy. This customizability allows end-users to tailor valves precisely to their working environments, ensuring seamless integration and efficiency. It is essential to emphasize the comprehensive support and service frameworks that accompany the implementation of long stem gate valves. Leading manufacturers offer extensive service packages that include installation guidance, maintenance support, and training programs. Such support structures are pivotal for optimizing valve performance and extending operational life, reinforcing the trust that industries place in these critical components. In conclusion, the long stem gate valve embodies a remarkable confluence of experience, expertise, authority, and trust. Its significant role in enabling precise control over fluid and gas flow is unparalleled, making it an indispensable asset in demanding industrial scenarios. Whether confronting extreme temperatures, high pressures, or corrosive environments, the long stem gate valve ensures operators have a reliable and effective tool at their disposal, maintaining its standing as a cornerstone of modern industrial valve solutions.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025