Nov . 11, 2024 19:03 Back to list

foot valve

Understanding Foot Valves A Crucial Component in Fluid Mechanics

Foot valves are essential devices used primarily in pumping systems, especially in water supply and irrigation applications. Their primary purpose is to allow the flow of liquid in one direction while preventing backflow, ensuring that the water reaches its intended destination efficiently. This article explores the function, types, and importance of foot valves in various applications.

What is a Foot Valve?

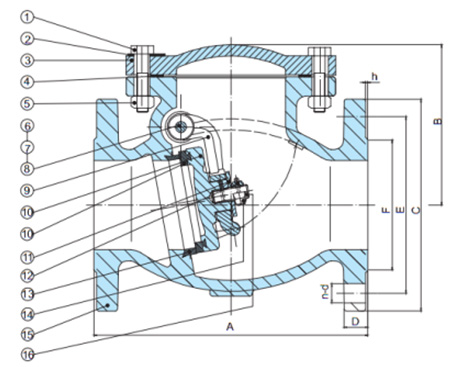

A foot valve is essentially a type of check valve that is positioned at the end of a suction line, submerged in a fluid source, such as a well or a water tank. It is equipped with a screen or strainer that prevents debris and sediment from entering the pump system. By allowing fluid to flow only in one direction, foot valves help maintain suction and facilitate the efficient operation of pumps.

How Do Foot Valves Work?

The operation of a foot valve is relatively straightforward. When the pump is activated, the pressure created pulls the liquid upward through the suction line. As the fluid flows, the foot valve opens, allowing liquid to enter the pump. Once the pump is turned off, the backward pressure created by gravity could potentially cause the flow to reverse. Here, the foot valve plays its crucial role by closing tightly to prevent backflow, thereby maintaining the prime in the suction line.

Types of Foot Valves

Foot valves come in various designs suitable for different applications

1. Swing Type Foot Valves These are equipped with a swing disk that opens with fluid flow. They are commonly used in larger systems where the backflow risk is significant.

2. Lift Type Foot Valves These have a mechanism that lifts the disc off its seat when the pump operates. This type is often used in smaller or less complex systems where space may be limited.

foot valve

3. Screened Foot Valves These include a strainer to filter out debris. They are often used in well pumps to prevent sand and other particles from entering the pump mechanism.

4. Non-Metallic Foot Valves Made from plastic materials, these valves are resistant to corrosion and are often preferred in applications involving harsh chemicals.

Importance of Foot Valves

The significance of foot valves cannot be overstated in fluid mechanics. They ensure the following

1. Prevent Backflow By stopping the reverse flow of liquids, foot valves help maintain system integrity and prevent damage to pumps and other components.

2. Provide Reliable Operation A properly functioning foot valve ensures that the pump remains primed, which is crucial for preventing dry runs that can lead to pump failure.

3. Reduce Maintenance Costs By preventing sediment and debris from entering the pump system, foot valves contribute to lower maintenance costs and extend the life of the pump.

4. Enhanced Efficiency With proper flow management, foot valves allow pumps to operate at optimal efficiency, which is vital for energy conservation and cost management.

Conclusion

Foot valves are small but mighty components in the world of fluid mechanics. They serve critical functions in pumping systems, ensuring that operations run smoothly and efficiently. Whether used in agricultural irrigation systems, industrial applications, or residential water supply, understanding their function and proper maintenance is fundamental to achieving reliable performance. Investing in quality foot valves can lead to considerable long-term benefits, saving time, money, and resources in various fluid management applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025