Nov . 03, 2024 15:27 Back to list

flanged swing check valve

Flanged Swing Check Valve An Overview

Flanged swing check valves are crucial components in various industrial applications, particularly in piping systems, where backflow prevention is essential. These valves operate based on a simple yet effective mechanism that allows fluid to flow in one direction while automatically closing to prevent reverse flow. The design and functionality of flanged swing check valves make them a popular choice in water treatment, oil and gas, and chemical processing industries.

Design and Construction

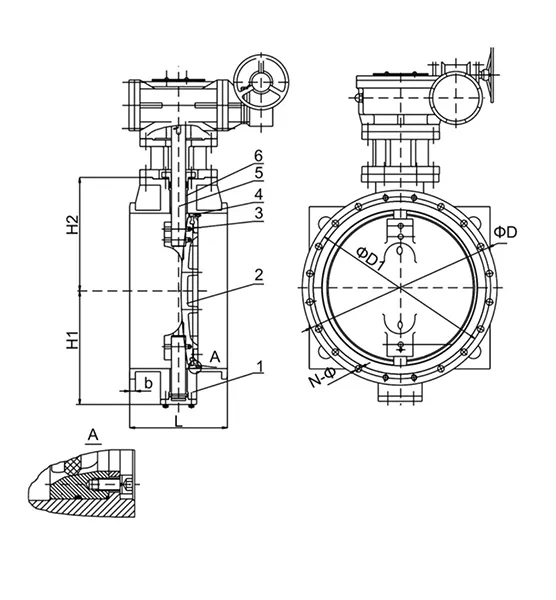

The flanged swing check valve is primarily constructed from durable materials such as cast iron, stainless steel, or bronze, chosen for their ability to withstand high pressures and corrosive environments. The valve consists of a disc, which swings on a hinge or pivot point, and is mounted at a right angle to the flow direction. When fluid moves in the desired direction, the disc swings open, allowing the fluid to pass through. However, when the flow direction reverses, the disc swings closed due to gravity and flow resistance, effectively sealing the valve to prevent backflow.

Flanges on both ends of the valve provide ease of installation and maintenance. These flanges allow the valve to be connected to adjoining pipes using bolts, ensuring a secure and leak-proof fit. Available in various sizes, flanged swing check valves can cater to different pipe diameters, making them versatile for various installations.

Advantages of Flanged Swing Check Valves

1. Prevention of Backflow The primary function of any check valve is to prevent backflow, which can cause significant damage to pipelines and associated equipment. Flanged swing check valves excel in this regard due to their simple yet robust design.

flanged swing check valve

2. Low Pressure Drop Compared to other types of check valves, flanged swing check valves typically exhibit lower pressure drops across the valve, making them energy-efficient, especially in high-flow applications.

3. Minimal Maintenance Due to their sturdy construction, these valves require minimal maintenance. Regular inspections can ensure their functionality without frequent repairs, reducing downtime in industrial operations.

4. Wide Range of Applications Flanged swing check valves are suitable for various applications, including water supply systems, wastewater treatment plants, and other fluid handling systems where backflow prevention is critical.

Installation and Maintenance Considerations

While flanged swing check valves are relatively easy to install, it’s essential to consider the flow direction indicated on the valve body. Installing the valve incorrectly can lead to operational failures. Maintenance involves routine inspections to check for wear and tear, ensuring the sealing surface is intact and that the disc operates smoothly.

Conclusion

Flanged swing check valves are indispensable in modern fluid management systems. Their ability to prevent backflow, coupled with their low pressure drop and ease of maintenance, makes them a preferred choice for engineers and operators alike. Understanding the components, advantages, and maintenance of these valves is crucial for ensuring reliable and efficient system operations. As industries continue to advance, the importance of reliable check valves like the flanged swing check valve will undoubtedly remain significant in preserving the integrity and efficiency of piping systems worldwide.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025