Feb . 06, 2025 02:23 Back to list

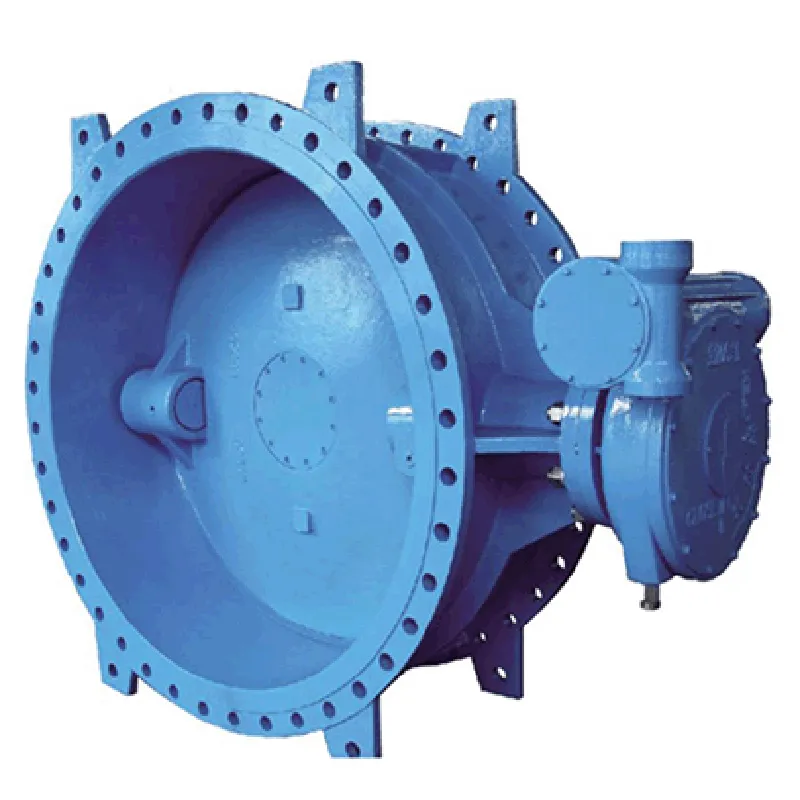

flanged butterfly valve

The evolution of industrial valve technology has led to the development of various types of valves, each suited to specific applications. Among these, the flanged butterfly valve stands out as a critical component in industrial systems, offering a blend of efficiency, reliability, and ease of use. This article delves into the intricacies of the flanged butterfly valve, projecting an in-depth understanding grounded in practical experience and technical expertise.

When considering the trustworthiness of flanged butterfly valves, one must look at the rigor of quality assurance protocols during the manufacturing process. Reputable manufacturers adhere to stringent industry standards—ISO, ANSI, and API certifications—guaranteeing that each valve has undergone rigorous testing for performance, durability, and safety. This assurance builds confidence among users, who can rely on these valves to function flawlessly in high-stakes industrial environments. Furthermore, the growing emphasis on environmental responsibility in industrial operations has spotlighted the role of valves in reducing emissions and energy consumption. The design efficiency of flanged butterfly valves aids in minimizing fluid resistance, which can lead to significant energy savings. Additionally, their capability to effectively manage with a tight shut-off helps prevent wastage and potential environmental hazards, aligning industrial operations with sustainable practices. Speaking from real-world experience, one of the understated yet significant benefits of flanged butterfly valves is their compatibility with automation. The integration of electric or pneumatic actuators transforms these valves into intelligent components of automated systems. This capability not only enhances operational efficiency but also empowers facilities with proactive maintenance strategies through real-time monitoring and control. In conclusion, the flanged butterfly valve emerges as a superior choice in the realm of fluid management. Its blend of reliable performance, adaptability to diverse applications, and ease of maintenance makes it a preferred solution across various industries. As advancements in material sciences and automation technology continue to evolve, the flanged butterfly valve is set to offer even greater levels of precision and reliability, reinforcing its status as an indispensable tool in modern engineering systems.

When considering the trustworthiness of flanged butterfly valves, one must look at the rigor of quality assurance protocols during the manufacturing process. Reputable manufacturers adhere to stringent industry standards—ISO, ANSI, and API certifications—guaranteeing that each valve has undergone rigorous testing for performance, durability, and safety. This assurance builds confidence among users, who can rely on these valves to function flawlessly in high-stakes industrial environments. Furthermore, the growing emphasis on environmental responsibility in industrial operations has spotlighted the role of valves in reducing emissions and energy consumption. The design efficiency of flanged butterfly valves aids in minimizing fluid resistance, which can lead to significant energy savings. Additionally, their capability to effectively manage with a tight shut-off helps prevent wastage and potential environmental hazards, aligning industrial operations with sustainable practices. Speaking from real-world experience, one of the understated yet significant benefits of flanged butterfly valves is their compatibility with automation. The integration of electric or pneumatic actuators transforms these valves into intelligent components of automated systems. This capability not only enhances operational efficiency but also empowers facilities with proactive maintenance strategies through real-time monitoring and control. In conclusion, the flanged butterfly valve emerges as a superior choice in the realm of fluid management. Its blend of reliable performance, adaptability to diverse applications, and ease of maintenance makes it a preferred solution across various industries. As advancements in material sciences and automation technology continue to evolve, the flanged butterfly valve is set to offer even greater levels of precision and reliability, reinforcing its status as an indispensable tool in modern engineering systems.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025