Oct . 12, 2024 11:37 Back to list

Understanding the Functionality and Benefits of Double Swing Check Valves in Piping Systems

Understanding Double Swing Check Valves Functionality and Applications

In various engineering and industrial applications, ensuring a reliable flow of fluids is crucial. One of the essential components used for this purpose is the check valve, specifically the double swing check valve. This type of valve plays a significant role in preventing backflow, maintaining the efficiency of the system, and safeguarding equipment from potential damage due to reverse flow. In this article, we will explore the functionality, design, advantages, and applications of double swing check valves.

What is a Double Swing Check Valve?

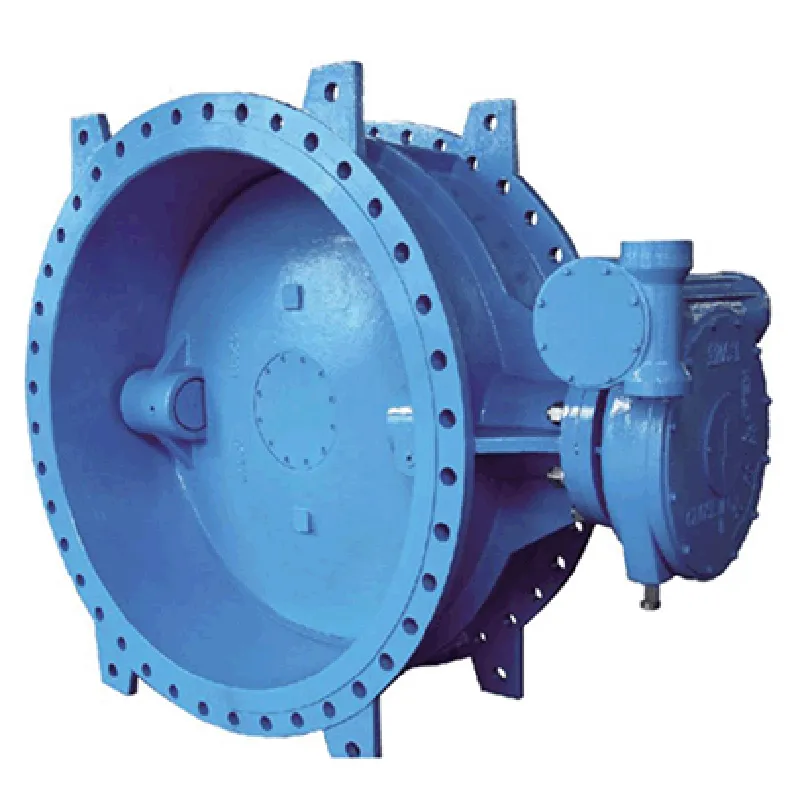

A double swing check valve is a type of non-return valve that consists of two hinged discs that swing open to allow fluid flow in one direction and close to prevent backflow. Unlike single swing check valves, which have a single disc, double swing check valves use two discs for improved performance and reduced hydraulic resistance. This design enhances the valve's ability to operate effectively under varying flow conditions, making it suitable for various applications.

How Does a Double Swing Check Valve Work?

The operational mechanism of a double swing check valve is relatively straightforward. When fluid flows in the desired direction, the pressure pushes the discs apart, allowing the fluid to pass through. As the flow decreases or reverses, the discs close due to gravity and the weight of the fluid, thereby sealing off the valve. This closure is swift, preventing any backflow that could compromise the system's integrity.

Design Features

One of the key features of double swing check valves is their ability to minimize turbulence and pressure drop. The design allows for a streamlined path for fluid, reducing the energy loss that typically occurs with other types of valves. Additionally, the use of two discs enables the valve to operate efficiently even in large pipelines and high-flow scenarios.

Materials used in the construction of double swing check valves vary widely, from stainless steel to ductile iron and plastic, depending on the specific application requirements, including temperature, pressure, and the nature of the fluid being handled.

Advantages of Double Swing Check Valves

1. Reduced Pressure Drop As previously mentioned, double swing check valves are designed to allow for a smooth flow of fluids, which significantly reduces pressure drop compared to other types of check valves.

2. Higher Flow Rates The dual-disc design allows for higher flow rates, making them ideal for large-scale applications where efficiency is critical.

double swing check valve

3. Durability These valves are built to withstand harsh conditions, including high pressure, temperature, and corrosive environments, depending on the materials used.

4. Ease of Maintenance Many double swing check valves are designed to be easily disassembled for inspection and maintenance, allowing for quick repairs and ensuring long service life.

5. Versatility Double swing check valves can be used in various applications, including water and wastewater treatment, chemical processing, and HVAC systems.

Applications

Double swing check valves are widely used across numerous industries due to their effectiveness and reliability. Some common applications include

1. Water Supply Systems In municipal water systems, these valves prevent backflow, ensuring clean and safe drinking water.

2. Wastewater Treatment Plants They help in maintaining the proper flow of wastewater and preventing contamination of clean water sources.

3. Chemical Processing In the chemical industry, double swing check valves are crucial for preventing backflow that could lead to hazardous situations.

4. Fire Protection Systems These valves are essential in fire protection systems to ensure that water flows in only one direction and does not backflow into the supply lines.

5. HVAC Systems In heating and cooling systems, double swing check valves help maintain proper flow direction and system efficiency.

Conclusion

Double swing check valves are an indispensable component in numerous fluid handling systems. Their design maximizes flow efficiency while providing robust protection against backflow, which can lead to system failures and safety hazards. Understanding their functionality, advantages, and applications is crucial for engineers and system designers seeking to optimize fluid management in various industrial settings. As technology advances, the materials and designs of these valves will continue to evolve, further enhancing their capabilities and reliability in the field.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025