Jan . 09, 2025 11:55 Back to list

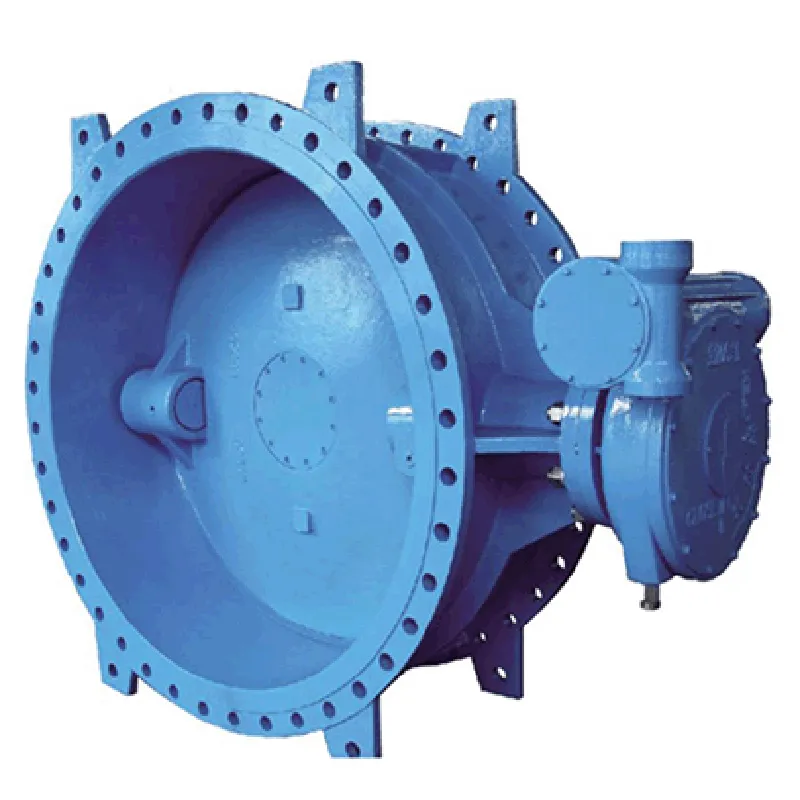

Ball Check Valve

Check valves, often overlooked yet crucial for various systems, serve as reliable gatekeepers in numerous applications. From ensuring safe operations in industrial pipelines to maintaining water system efficiency, check valves are indispensable in fluid dynamics. Their core function—preventing backflow—makes them essential in safeguarding equipment, systems, and infrastructures from potential damage or inefficiency.

An authoritative understanding of check valve dynamics not only informs better product selection but also contributes to efficient system design. Manufacturers and suppliers often provide detailed specifications and guidelines, offering valuable insights into optimal use. Collaborating with experienced professionals during selection and installation phases ensures check valves operate seamlessly within your system's framework. The trustworthiness of check valves largely depends on their quality and adherence to industry standards. Reputable manufacturers ensure their products undergo rigorous testing and certification processes, aligning with standards such as ISO, ANSI, and NSF. Investing in such certified valves can reassure users of the product's reliability and performance, establishing trust in their application. One must also consider real-life experiences shared by industry veterans and users. Case studies and customer testimonials provide practical insights into performance and durability in various scenarios. Such experiences not only validate product claims but also guide new users in making informed decisions. Platforms offering comprehensive reviews and comparisons based on user feedback can be immensely valuable in navigating the broad array of check valve options available in the market. In essence, the efficacy of check valves hinges on a detailed understanding of their types, applications, and operational intricacies. By leveraging expertise and authoritative resources, users can ensure the selection of high-quality, trustworthy valves suited to their specific requirements, ultimately enhancing system efficiency and reliability. Emphasizing maintenance and user experiences further strengthens the application of these critical components, cementing their role as key contributors to system integrity and performance.

An authoritative understanding of check valve dynamics not only informs better product selection but also contributes to efficient system design. Manufacturers and suppliers often provide detailed specifications and guidelines, offering valuable insights into optimal use. Collaborating with experienced professionals during selection and installation phases ensures check valves operate seamlessly within your system's framework. The trustworthiness of check valves largely depends on their quality and adherence to industry standards. Reputable manufacturers ensure their products undergo rigorous testing and certification processes, aligning with standards such as ISO, ANSI, and NSF. Investing in such certified valves can reassure users of the product's reliability and performance, establishing trust in their application. One must also consider real-life experiences shared by industry veterans and users. Case studies and customer testimonials provide practical insights into performance and durability in various scenarios. Such experiences not only validate product claims but also guide new users in making informed decisions. Platforms offering comprehensive reviews and comparisons based on user feedback can be immensely valuable in navigating the broad array of check valve options available in the market. In essence, the efficacy of check valves hinges on a detailed understanding of their types, applications, and operational intricacies. By leveraging expertise and authoritative resources, users can ensure the selection of high-quality, trustworthy valves suited to their specific requirements, ultimately enhancing system efficiency and reliability. Emphasizing maintenance and user experiences further strengthens the application of these critical components, cementing their role as key contributors to system integrity and performance.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025