pro . 14, 2024 04:10 Back to list

Understanding Globe Check Valves and Their Applications in Fluid Control Systems

Understanding Globe Check Valves Functionality, Applications, and Benefits

In the world of fluid dynamics, valves play a pivotal role in controlling the flow of liquids and gases in various industrial systems. Among the types of valves, the globe check valve stands out due to its unique design and functionality. This article seeks to provide an insightful overview of globe check valves, exploring their purpose, construction, applications, and benefits.

What is a Globe Check Valve?

A globe check valve is a specific type of valve that combines the characteristics of a globe valve and a check valve. It is primarily designed to allow fluid flow in one direction while preventing backflow, thus acting as a non-return valve. This dual functionality makes it an essential component in many piping systems.

The globe check valve comprises a spherical body with an internal baffle that creates a flow path, allowing for good control of fluid movement. The moving part of the valve, typically a disc or a ball, alters the flow path's diameter to either restrict or permit flow based on pressure variations within the system.

How Does a Globe Check Valve Work?

The working principle of a globe check valve is relatively straightforward. When fluid flows in the desired direction, it pushes the disc or ball downstream, effectively opening the valve. If there is a reduction in pressure or a reverse flow, the disc or ball is pushed back against the seat, closing the valve to prevent backflow. This mechanism protects the upstream system from potential damage caused by reverse flow, which can lead to contamination or failure of equipment.

Key Features of Globe Check Valves

1. Design Flexibility Globe check valves come in various designs and sizes, making them adaptable to numerous applications and environments. Manufacturers can customize these valves according to the specific requirements of a project.

2. Durability Made from robust materials such as brass, stainless steel, or cast iron, globe check valves are durable and resistant to corrosion, enabling them to function effectively in demanding conditions.

3. Easy Maintenance Unlike some other valve types, globe check valves have a simple construction that allows for easier maintenance and repair. This quality can significantly reduce downtime in industrial settings.

4. Flow Control While primarily serving as check valves, globe check valves provide good throttling capabilities, allowing operators to control flow rates more precisely.

Applications of Globe Check Valves

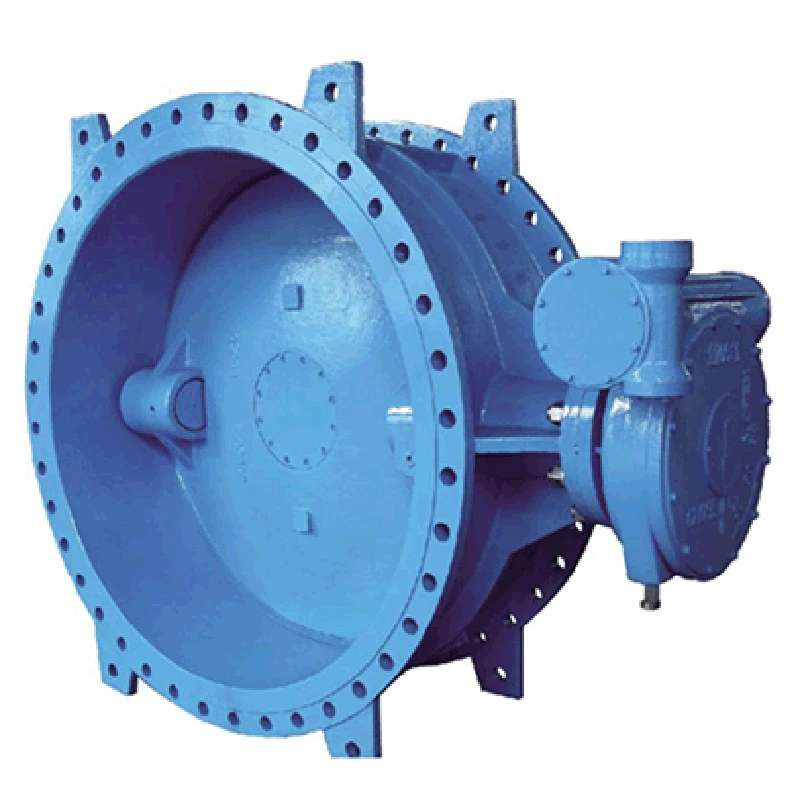

globe check valve

Globe check valves are widely used across various industries, including

- Water Treatment Plants They are crucial in preventing backflow in pipelines carrying treated water, ensuring that contaminants do not enter the clean water supply.

- Oil and Gas Industry These valves protect equipment from damage and contamination by preventing reverse flow in pipelines, refineries, and storage facilities.

- HVAC Systems In heating, ventilation, and air conditioning systems, globe check valves help maintain pressure levels and prevent backflow, contributing to system efficiency.

- Power Generation They are used in power plants to protect pumps and turbines from pressure surges and backflow, thus extending equipment lifespan.

Benefits of Using Globe Check Valves

The implementation of globe check valves offers various advantages

1. Enhanced System Integrity By preventing backflow, these valves help maintain the integrity of the entire system, reducing the risk of contamination and equipment failure.

2. Increased Efficiency The ability to regulate flow leads to improved operational efficiency, allowing processes to run smoothly with optimized resource use.

3. Cost-Effectiveness Although the initial investment may be higher compared to some simpler valve types, the long-term savings achieved through reduced maintenance and extended equipment life make globe check valves a cost-effective solution.

4. Safety Assurance By mitigating risks associated with backflow, globe check valves contribute to overall safety in industrial processes, protecting personnel and equipment alike.

Conclusion

In conclusion, globe check valves are integral components in various fluid systems, providing essential protection against backflow while offering advantages in flow control and maintenance. As industries continue to evolve, the demand for reliable and efficient valve solutions like globe check valves will persist, making them a long-standing choice for engineers and facility operators worldwide. Understanding their functionality and applications can help stakeholders make informed decisions that enhance efficiency and safety in their operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025