दिसम्बर . 01, 2024 02:55 Back to list

wafer type silent check valve

Introduction to Wafer Type Silent Check Valves

Wafer type silent check valves are essential components in fluid control systems, designed to prevent backflow and maintain system efficiency. These valves stand out for their compact design, lightweight structure, and ability to provide reliable operation with minimal noise. This article delves into the features, advantages, and applications of wafer type silent check valves, emphasizing their significance in various industries.

Design and Functionality

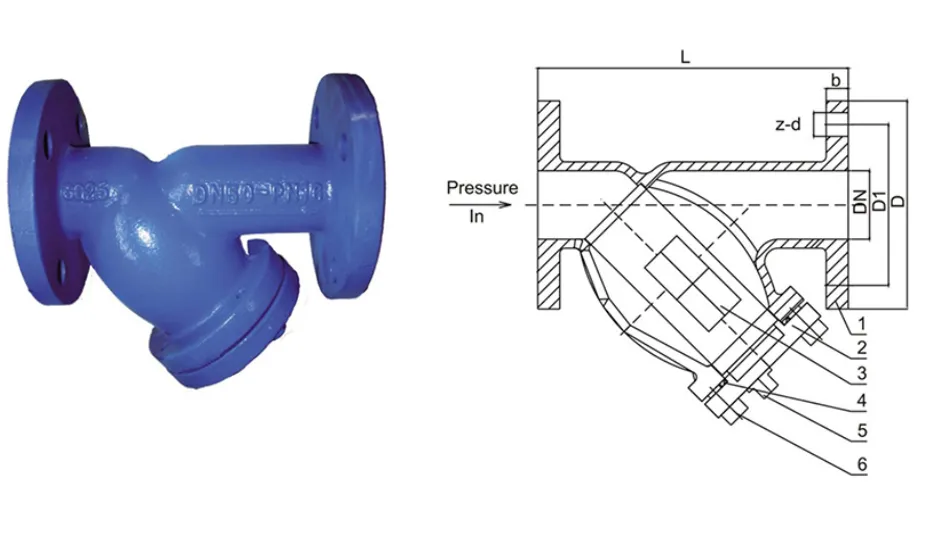

The wafer type silent check valve utilizes a unique design that incorporates a spring-loaded mechanism. This design allows the valve to open and close smoothly based on the flow of the fluid. When the fluid flows in the forward direction, the valve opens freely, allowing for unobstructed passage. However, if there is any reversal in the fluid flow, the valve closes quickly to prevent backflow, ensuring that the system remains safe and efficient.

One of the notable features of this valve type is its compact wafer design, which enables it to be installed between flanges without the need for additional space. This is particularly advantageous in applications where space is limited or where weight reduction is critical.

Advantages of Wafer Type Silent Check Valves

1. Minimal Noise As the name suggests, silent check valves operate with minimal noise, making them ideal for environments where noise reduction is a priority. This feature is especially important in residential and commercial buildings, where excessive noise can be disruptive.

wafer type silent check valve

2. Reduced Leakage Wafer type silent check valves are designed to minimize leakage, ensuring high system efficiency and reducing the risk of contamination in fluid systems.

3. Versatility These valves are suitable for a wide range of fluids, including water, oil, and gas, making them versatile in their application. They can be used in various industries, such as water treatment, power generation, and chemical processing.

4. Easy Installation and Maintenance The lightweight design and compact size of wafer type silent check valves simplify installation and maintenance processes. Their flange connections allow for easy integration into existing systems.

Applications

Wafer type silent check valves are widely used in numerous applications. In the water treatment industry, they help maintain the integrity of the flow system by preventing backflow, which can lead to contamination. In power generation, these valves play a crucial role in protecting pumps and ensuring system efficiency. Additionally, they are utilized in HVAC systems to prevent circulation issues and enhance system performance.

Conclusion

In summary, wafer type silent check valves are invaluable components in modern fluid control systems. Their innovative design, combined with various advantages such as minimal noise, reduced leakage, and versatility, makes them essential for many industrial applications. As industries continue to prioritize efficiency and sustainability, the demand for such reliable components will undoubtedly grow, solidifying the role of wafer type silent check valves in fluid management systems globally.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025