אוג . 28, 2024 23:14 Back to list

pipe dismantling joint

Understanding Pipe Dismantling Joints An Essential Component for Maintenance and Flexibility

In the realm of plumbing and pipeline systems, efficiency and adaptability are paramount. Among the myriad components that facilitate smooth operations, pipe dismantling joints play a crucial role. These specialized fittings enable easy disassembly of pipeline sections for maintenance, repair, or replacement without the need for extensive modifications or disruptions to the entire system.

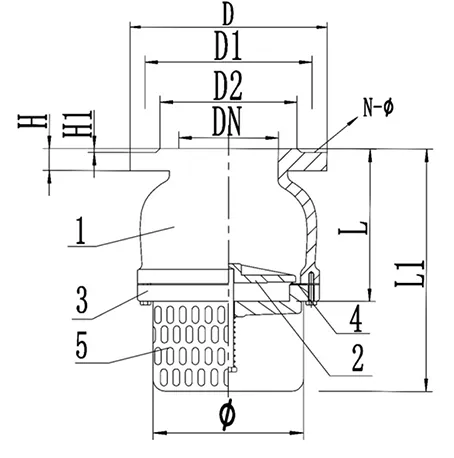

A pipe dismantling joint typically consists of two flange ends connected by a short section of pipe, which incorporates flexible elements that allow for movement and adjustment

. The design of these joints is ingenious; they provide a means to separate pipeline segments quickly, thereby reducing downtime and improving workflow. Additionally, the flexibility built into these joints helps accommodate thermal expansion and contraction, ensuring that the pipeline system remains intact under varying temperature conditions.One of the primary advantages of using dismantling joints is their ability to facilitate maintenance. In traditional piping systems, accessing specific sections for repair can be labor-intensive and time-consuming, often requiring the cutting and welding of pipes. This can lead to increased costs and prolonged service interruptions. Dismantling joints, however, allow technicians to easily disconnect segments of the pipeline, perform necessary inspections or repairs, and reassemble the system with minimal effort. This flexibility is particularly beneficial in industrial applications where downtime translates to significant financial losses.

pipe dismantling joint

Furthermore, dismantling joints are designed to withstand high pressures and corrosive environments, making them suitable for various applications, including water supply systems, sewage treatment facilities, and industrial processes. They are typically constructed from durable materials such as stainless steel or ductile iron, ensuring longevity and reliability. The ability to select the appropriate material based on the specific application enhances the effectiveness and resilience of the joint.

Another crucial aspect of pipe dismantling joints is their role in promoting efficiency in design and construction. By incorporating these joints into a pipeline system, engineers can create modular designs that simplify future expansions or modifications. When new sections of the pipeline are needed or when existing setups require reconfiguration, dismantling joints allow for seamless integration, thereby promoting a more flexible approach to infrastructure development.

In conclusion, pipe dismantling joints are an indispensable part of modern piping systems. Their ability to facilitate maintenance, withstand harsh conditions, and promote modularity makes them vital for enhancing the efficiency and reliability of pipelines. As industries continue to evolve and demand more adaptable infrastructure, the importance of dismantling joints is set to grow, ensuring that maintenance operations remain efficient and cost-effective. By investing in these innovative components, businesses can safeguard their operations and improve their overall function within a dynamic environment.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025