Dec . 10, 2024 06:55 Back to list

high performance butterfly valve

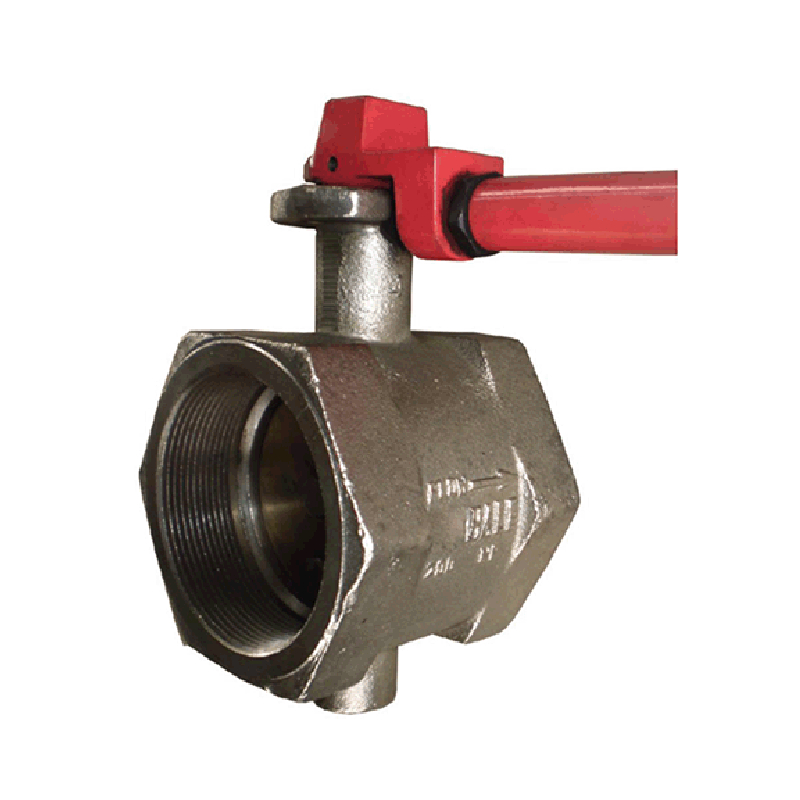

High-Performance Butterfly Valve A Key Component in Modern Fluid Control

In the realm of industrial applications, the butterfly valve stands out as a pivotal device designed to regulate the flow of fluids and gases. Among the myriad of valve types available, high-performance butterfly valves have gained a reputation for their efficiency, reliability, and versatility. These valves are essential components in various sectors, including water treatment, oil and gas, pharmaceuticals, food and beverage, and power generation.

Design and Functionality

High-performance butterfly valves feature a disc that rotates around a shaft to open or close the flow path. Unlike traditional butterfly valves, these advanced versions benefit from a superior design that enhances their performance in high-demand environments. Constructed from robust materials such as stainless steel, carbon steel, and various alloys, high-performance butterfly valves demonstrate superior resistance to corrosion, wear, and extreme temperatures.

The unique design of these valves allows for a streamlined flow, which minimizes turbulence and pressure drop. This characteristic not only enhances the efficiency of the system but also contributes to energy savings. In addition, the lightweight construction of the butterfly valve makes it easier to install and maintain, leading to reduced downtime and maintenance costs.

Applications and Benefits

One of the primary advantages of high-performance butterfly valves is their versatility. They can accommodate a wide range of fluids, including liquids, gases, and even slurries, making them suitable for numerous applications. In the oil and gas sector, for instance, these valves are crucial for controlling the flow of hydrocarbons through pipelines, ensuring safe and efficient operations.

high performance butterfly valve

In water treatment facilities, high-performance butterfly valves play a vital role in managing the distribution of treated water. Their ability to provide precise flow control helps maintain the quality of water, while also ensuring compliance with environmental regulations. Additionally, in the food and beverage industry, the sanitary design of these valves guarantees that products remain uncontaminated, upholding stringent health standards.

Technological Advancements

The evolution of high-performance butterfly valves has been significantly influenced by advancements in technology. Manufacturers are increasingly incorporating smart monitoring systems and automation features that allow for real-time tracking of valve performance. This integration of technology not only enhances operational efficiency but also contributes to proactive maintenance strategies, thereby reducing the likelihood of unexpected failures.

Moreover, the development of innovative sealing technologies has further improved the reliability of these valves. Advanced elastomeric seals and metal seat designs ensure leak-proof performance, even under high-pressure and high-temperature conditions. These improvements have expanded the use of high-performance butterfly valves in critical applications where failure is not an option.

Conclusion

High-performance butterfly valves emerge as a cornerstone in the landscape of fluid control technology. Their design, versatility, and advancements in materials and automation make them indispensable across various industries. As industries continue to evolve and demand more efficient, reliable, and safe solutions, high-performance butterfly valves will undoubtedly play a crucial role in meeting these challenges. Investing in these valves not only enhances operational efficiency but also contributes to sustainability goals, ensuring that industries can meet modern demands while minimizing their environmental impact. Whether facilitating the flow of essential resources or ensuring compliance with stringent regulations, high-performance butterfly valves are here to stay, driving innovation and efficiency in fluid management systems worldwide.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025