Dec . 10, 2024 19:29 Back to list

Butterfly Valve Equipped with Gearbox for Enhanced Control and Efficiency

Understanding Butterfly Valves with Gearboxes

Butterfly valves are essential components in various industrial applications, serving as a reliable method for regulating fluid flow. Among the different types of butterfly valves, those equipped with gearboxes stand out for their enhanced control and operational efficiency, making them a preferred choice in many engineering settings.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that utilizes a rotating disk to regulate flow. The disk, mounted on a rotating shaft, is positioned perpendicular to the flow direction when closed and aligned with it when opened. This simplistic design allows for quick operation, usually requiring just a 90-degree turn to open or close the valve fully.

The primary advantage of butterfly valves is their lightweight and compact nature, which allows for easy installation and maintenance. They are suitable for various media, including liquids, gas, and slurries, making them versatile in applications ranging from water supply and sewage to chemical processing and HVAC systems.

The Role of Gearboxes

In applications where higher torque is required to operate the valve, particularly in larger or more demanding systems, a gearbox is employed. Gearboxes serve as mechanical devices that increase the output torque while reducing the speed of the input shaft. This is crucial for butterfly valves because it allows for smoother operation, greater control over the flow, and reduced manual effort required to turn the valve.

Gearboxes are especially beneficial in large-diameter butterfly valves, where the force required to turn the valve can be substantial. By using a gearbox, operators can confidently manage the valve without the risk of manual failure or injury. Gearboxes also help in applications where remote operation is needed, as they can be coupled with electric actuators.

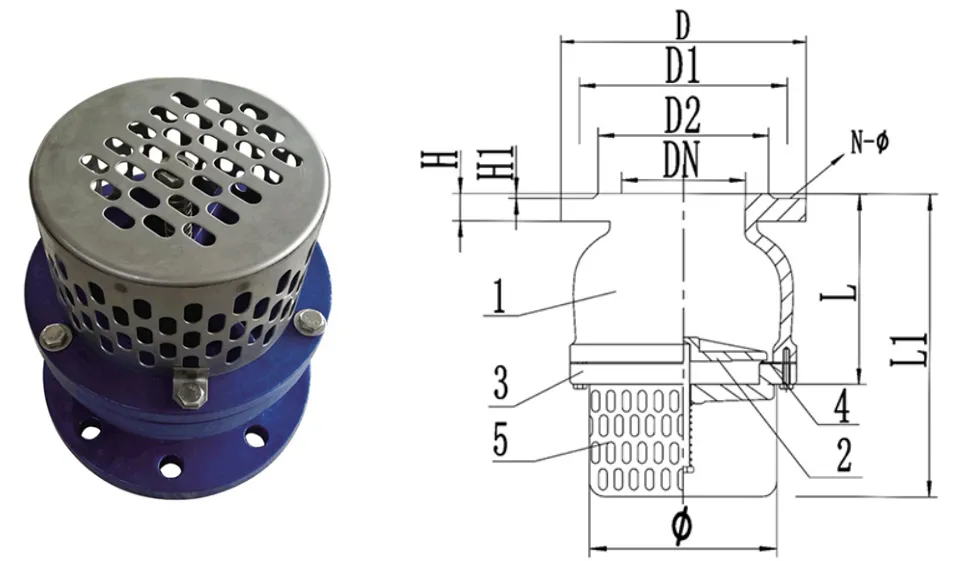

butterfly valve with gear box

Advantages of Using Gearbox-Equipped Butterfly Valves

1. Enhanced Control The combination of a butterfly valve with a gearbox provides improved control over the flow rate. This is particularly important in processes requiring precise flow regulation, such as in chemical manufacturing, where even slight variations can affect product quality.

2. Increased Durability Gearboxes protect the operating mechanism of the valve from excessive wear. By minimizing backlash and providing a gentle handle on the valve operation, they increase the longevity of both the valve and its components.

3. Safety In environments where high pressures or hazardous substances are involved, the added mechanical advantage of a gearbox allows operators to manage valves more securely and with reduced risk of accidents.

4. Automation Compatibility Many modern industrial processes are moving towards automation. Gearbox-equipped butterfly valves can easily be integrated with actuation systems, facilitating remote operation and monitoring. This not only increases efficiency but also enhances operational safety.

5. Cost-Effectiveness Although the initial cost of a gearbox-equipped valve may be higher than a standard valve, the reduction in maintenance costs, increased operational efficiency, and longevity often make them a more economical choice over time.

Conclusion

Butterfly valves with gearboxes represent a critical innovation in the field of fluid control. By combining the efficient flow regulation capabilities of butterfly valves with the enhanced operational control provided by gearboxes, industries can achieve greater reliability, safety, and efficiency in their processes. As the demand for better control systems continues to grow, the adoption of these advanced valves will likely increase, reinforcing their importance across various sectors.

Share