Nov . 21, 2024 23:44 Back to list

y strainer valve

Understanding Y-Strainer Valves An Essential Component in Fluid Systems

Y-strainer valves are pivotal components in various fluid systems, providing effective filtration and protection against unwanted debris. Their distinctive Y-shaped design is not just for aesthetics; it serves a functional purpose that significantly contributes to the efficiency and longevity of piping systems. This article delves into the importance, functionality, and applications of Y-strainer valves.

What is a Y-Strainer Valve?

A Y-strainer valve is a type of mechanical device used to filter out solid particulates from liquids or gases in a pipeline. The name “Y-strainer” is derived from its shape, resembling the letter Y. This design allows for easy access to the filtration element, which is typically a mesh or perforated screen, making maintenance convenient. Y-strainers are usually installed in the main line of a system and can be oriented in various positions, though horizontal installation is most common.

How Does It Work?

The function of a Y-strainer valve is straightforward yet highly effective. Fluid flows into the strainer through the inlet, where it encounters the filtering element. The mesh or screen captures debris such as dirt, rust, or other contaminants, preventing them from passing through the system. Clean fluid continues through the outlet, ensuring that downstream equipment operates without obstruction. The design minimizes pressure drop, making Y-strainers an efficient choice for various applications.

Applications of Y-Strainers

Y-strainer valves are incredibly versatile and find applications across numerous industries. They are extensively used in

1. Water Treatment In treatment plants, Y-strainers protect pumps and other equipment from debris that may contaminate the water source.

2. Chemical Processing Chemical facilities utilize Y-strainers to safeguard sensitive equipment from particles that could interfere with delicate processes.

y strainer valve

3. HVAC Systems In heating, ventilation, and air conditioning systems, these strainers filter out sediment and particles to ensure efficient operation and optimal performance.

4. Food and Beverage Industry Y-strainers help maintain hygiene standards by filtering contaminants from liquids, ensuring the safety and quality of food products.

5. Power Generation In power plants, Y-strainers are used to protect cooling systems and other critical equipment, enhancing operational reliability.

Advantages of Y-Strainer Valves

The advantages of Y-strainer valves are manifold. Firstly, their simple design promotes ease of maintenance; users can easily clean or replace the filtering element without taking the entire system offline. Secondly, Y-strainers are available in various sizes and materials, making them suitable for different applications and environments. Lastly, they help extend the lifespan of downstream equipment by preventing potential damage caused by debris.

Maintenance Considerations

While Y-strainer valves provide significant benefits, regular maintenance is crucial to ensure their efficacy. Depending on the specific application and the amount of debris in the fluid, strainers should be checked periodically. Cleaning the strainer can be achieved through simple disassembly and rinsing of the mesh, which should be done according to the manufacturer's recommendations to avoid any operational issues.

Conclusion

Y-strainer valves are essential components in maintaining the integrity and efficiency of fluid systems across various industries. Their reliable filtration capabilities protect equipment from contaminants, enhancing operational performance and longevity. By understanding the functionality and applications of Y-strainer valves, industries can better appreciate their role and implement them effectively to improve system reliability. Whether in industrial, municipal, or residential applications, Y-strainers prove to be invaluable assets in the realm of fluid management.

Share

-

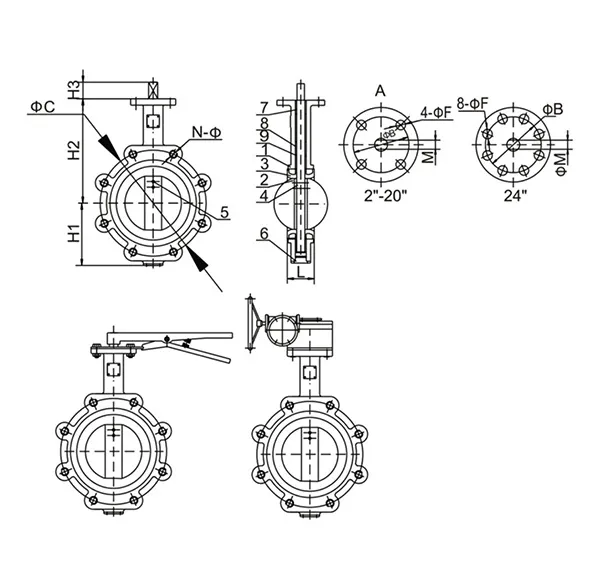

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025