Jan . 24, 2025 02:49 Back to list

butterfly valve semi lug type

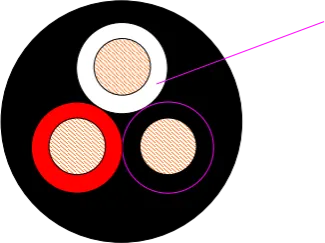

Selecting the right lug type butterfly valve for industrial applications demands a blend of technical knowledge, practical experience, and a strong understanding of fluid dynamics. Distinguished for their compact design and effective sealing capabilities, lug type butterfly valves play a crucial role in regulating flow in pipelines and ensuring process efficiency.

Moreover, understanding flow characteristics is critical. Butterfly valves are designed with disk movement resembling the wing action, offering minimal restriction and pressure drop across the valve when open. This unique feature results in significant energy savings over time, which is crucial for cost-sensitive operations. Discussing authoritativeness, lug type butterfly valves are often manufactured according to stringent industry standards, such as ANSI, API, or ISO. These certifications ensure that the products meet high-quality benchmarks which are critical for operational safety and reliability. Consulting with a credible supplier with a track record of compliant manufacturing practices is a prudent step. Trustworthiness in the supply chain cannot be overstated, especially for mission-critical applications. Ensuring that the supplier provides comprehensive documentation and test reports for the valves is essential. A reputable supplier will offer warranties and after-sales support, reinforcing the product's reliability. Additionally, opting for manufacturers known for consistent quality and customer service is highly advisable. In conclusion, the selection of lug type butterfly valves should be underpinned by a thorough understanding of application requirements and industry standards. Drawing from real-world experience, expertise in technical specifications, and a discerning eye for credible manufacturers, industry professionals can choose the right valve that ensures efficiency, longevity, and safety in their operations. This approach not only maximizes operational performance but also enhances overall process integrity.

Moreover, understanding flow characteristics is critical. Butterfly valves are designed with disk movement resembling the wing action, offering minimal restriction and pressure drop across the valve when open. This unique feature results in significant energy savings over time, which is crucial for cost-sensitive operations. Discussing authoritativeness, lug type butterfly valves are often manufactured according to stringent industry standards, such as ANSI, API, or ISO. These certifications ensure that the products meet high-quality benchmarks which are critical for operational safety and reliability. Consulting with a credible supplier with a track record of compliant manufacturing practices is a prudent step. Trustworthiness in the supply chain cannot be overstated, especially for mission-critical applications. Ensuring that the supplier provides comprehensive documentation and test reports for the valves is essential. A reputable supplier will offer warranties and after-sales support, reinforcing the product's reliability. Additionally, opting for manufacturers known for consistent quality and customer service is highly advisable. In conclusion, the selection of lug type butterfly valves should be underpinned by a thorough understanding of application requirements and industry standards. Drawing from real-world experience, expertise in technical specifications, and a discerning eye for credible manufacturers, industry professionals can choose the right valve that ensures efficiency, longevity, and safety in their operations. This approach not only maximizes operational performance but also enhances overall process integrity.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025