Nov . 07, 2024 01:37 Back to list

flange type silent check valve

Flange Type Silent Check Valve An Overview

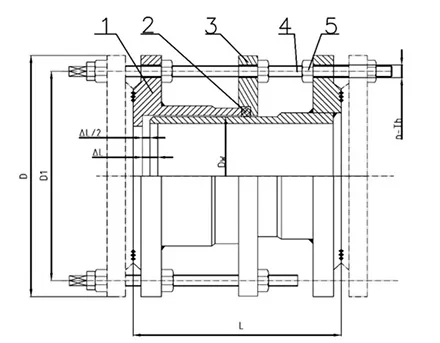

The flange type silent check valve is an essential component in various piping systems, designed to allow fluid flow in one direction while preventing backflow. This type of valve is particularly favored in industries such as water treatment, oil and gas, and chemical processing due to its efficient design and operational reliability.

One of the primary functions of the silent check valve is to maintain system integrity by preventing reverse flow, which could lead to costly damages and inefficiencies. The valve operates silently, which is a significant advantage over traditional swing check valves that may create noise during operation. This feature makes the flange type silent check valve especially useful in residential and commercial applications where noise reduction is a priority.

The construction of a flange type silent check valve typically involves high-quality materials such as stainless steel, ductile iron, or plastic, ensuring durability and resistance to corrosion

. The valve is designed with flanged connections, allowing for easy installation and maintenance. This design facilitates a secure and leak-proof connection to the piping system, minimizing the risk of fluid leakage.flange type silent check valve

Operationally, the silent check valve uses a spring-loaded mechanism that ensures swift closure when there is a risk of backflow. The valve disk is engineered to respond quickly to changes in fluid flow, sealing off the reverse direction effectively. This mechanism is crucial in applications where backflow could introduce contaminants or disrupt system operation.

In addition to its primary function of preventing backflow, the flange type silent check valve also contributes to system efficiency. By minimizing pressure fluctuations and reducing the energy required to maintain fluid flow, it enables systems to operate smoothly and economically. The compact design of these valves allows them to be fitted into various configurations without taking up excessive space.

Regular maintenance is vital for the optimal performance of flange type silent check valves. Users should perform routine inspections to check for signs of wear or damage and ensure that the sealing mechanisms are functioning correctly. Proper maintenance can extend the lifespan of the valve and prevent unexpected failures that could disrupt operations.

In conclusion, the flange type silent check valve is a vital component that enhances the efficiency and reliability of fluid transport systems. Its noise-free operation, robust design, and effective backflow prevention make it an ideal choice for a variety of industrial and commercial applications. As industries continue to prioritize efficiency and safety, the flange type silent check valve will remain an essential fixture in modern piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025