Jan . 09, 2025 12:19 Back to list

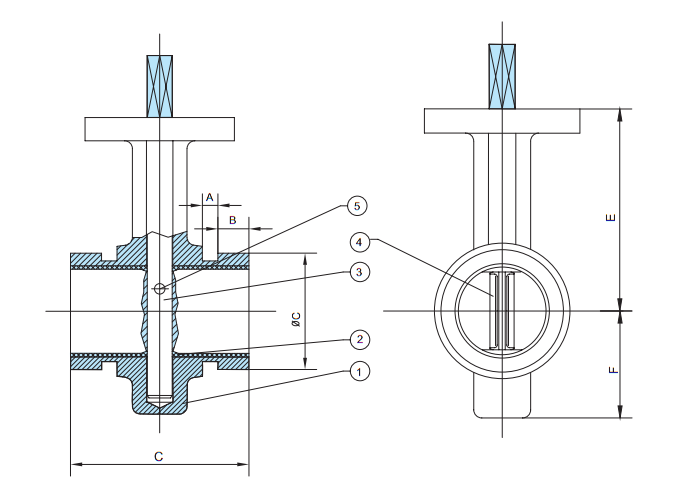

ball type check valve

In the heart of fluid control systems lies an unsung hero the check valve. This seemingly simple component plays a vital role in ensuring the seamless operation of diverse applications ranging from household plumbing to complex industrial processes. By understanding the mechanics and applications of check valves, users can optimize performance, prevent system failures, and enhance operational efficiency—attributes that contribute to the product's robust reputation for reliability and performance.

Trust in the performance of check valves is grounded in rigorous testing and adherence to international standards. A reputable check valve undergoes meticulous evaluation, including pressure tests, flow rate analysis, and thermal cycling, to ensure its capability to withstand designated operating conditions. Moreover, certifications from recognized bodies, such as ISO and API, further affirm the check valve's reliability, ensuring users receive a product that meets stringent quality requirements. Practical experience showcases that regular maintenance prolongs the lifespan of check valves and sustains system integrity. Routine inspection to check for wear or debris accumulation can prevent potential malfunctions. In industrial settings, establishing a preventive maintenance schedule is advisable to minimize downtime and extend service life, thereby optimizing operation costs and productivity. In summary, the check valve, with its crucial role in fluid dynamics, represents a pinnacle of engineering simplicity infused with technical expertise. By aligning specific valve types and materials with their intended applications, businesses and individuals alike can achieve reliable operation and safeguard their systems against the adversities of improper flow management. The continued evolution in check valve technology promises enhanced performance, reliability, and sustainability, affirming their indispensable role in fluid control systems across the globe.

Trust in the performance of check valves is grounded in rigorous testing and adherence to international standards. A reputable check valve undergoes meticulous evaluation, including pressure tests, flow rate analysis, and thermal cycling, to ensure its capability to withstand designated operating conditions. Moreover, certifications from recognized bodies, such as ISO and API, further affirm the check valve's reliability, ensuring users receive a product that meets stringent quality requirements. Practical experience showcases that regular maintenance prolongs the lifespan of check valves and sustains system integrity. Routine inspection to check for wear or debris accumulation can prevent potential malfunctions. In industrial settings, establishing a preventive maintenance schedule is advisable to minimize downtime and extend service life, thereby optimizing operation costs and productivity. In summary, the check valve, with its crucial role in fluid dynamics, represents a pinnacle of engineering simplicity infused with technical expertise. By aligning specific valve types and materials with their intended applications, businesses and individuals alike can achieve reliable operation and safeguard their systems against the adversities of improper flow management. The continued evolution in check valve technology promises enhanced performance, reliability, and sustainability, affirming their indispensable role in fluid control systems across the globe.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025