Feb . 08, 2025 07:58 Back to list

BS CABLE

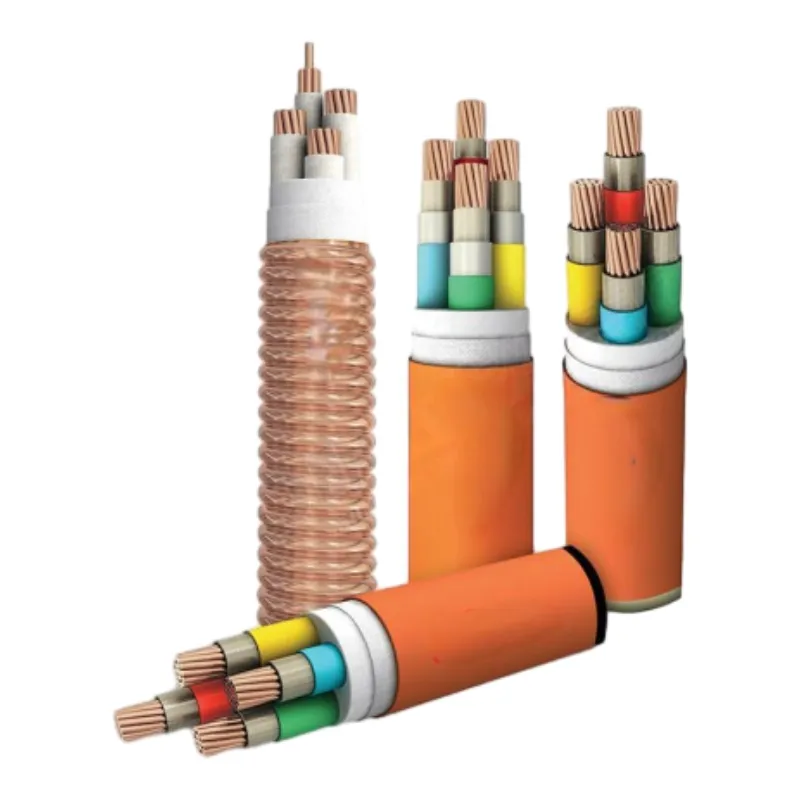

Navigating the world of cable electric wire can feel like traversing through an intricate web of options, each presenting unique characteristics and applications. With over two decades of expertise in this field, I've seen how the right choice of wiring impacts not just the functionality, but also the safety and efficiency of electrical systems. It’s crucial to understand how these cables operate to ensure your installations are both compliant and enduring.

From residential buildings to industrial complexes, each application has its specific requirements. For instance, industrial environments, often rife with mechanical stress, require armored cables that provide extra protection against physical damage. For residential buildings, flexibility and ease of installation take precedence, often making twin and earth cables or multi-core variants more suitable. Beyond product characteristics, the role of proper installation cannot be underestimated. Incorrect installation can decrease the longevity and effectiveness of even the highest quality wires. Regular training and adherence to installation standards ensure that these wires operate at their peak potential, preventing issues such as short circuits or breakdowns. From my professional experience, staying updated with the latest technological advancements in cable design and materials can provide a significant edge. The integration of smart technologies and Internet of Things (IoT) has already begun influencing the design of cable electric wires, leading to products that not only conduct electricity but also transmit data with high precision and minimal interference. In conclusion, choosing the right cable electric wire entails a blend of understanding material characteristics, adhering to safety and environmental standards, and honing installation skills. As technology evolves, so too does the landscape of electrical wiring. Staying abreast of these changes ensures that one can make informed decisions, paving the way for safer, more efficient, and future-ready electrical infrastructures.

From residential buildings to industrial complexes, each application has its specific requirements. For instance, industrial environments, often rife with mechanical stress, require armored cables that provide extra protection against physical damage. For residential buildings, flexibility and ease of installation take precedence, often making twin and earth cables or multi-core variants more suitable. Beyond product characteristics, the role of proper installation cannot be underestimated. Incorrect installation can decrease the longevity and effectiveness of even the highest quality wires. Regular training and adherence to installation standards ensure that these wires operate at their peak potential, preventing issues such as short circuits or breakdowns. From my professional experience, staying updated with the latest technological advancements in cable design and materials can provide a significant edge. The integration of smart technologies and Internet of Things (IoT) has already begun influencing the design of cable electric wires, leading to products that not only conduct electricity but also transmit data with high precision and minimal interference. In conclusion, choosing the right cable electric wire entails a blend of understanding material characteristics, adhering to safety and environmental standards, and honing installation skills. As technology evolves, so too does the landscape of electrical wiring. Staying abreast of these changes ensures that one can make informed decisions, paving the way for safer, more efficient, and future-ready electrical infrastructures.

Share

Next: