Jan . 01, 2025 11:47 Back to list

Actuated Valve Technologies for Enhanced Control in Industrial Applications

Understanding Actuated Valves Key Components and Applications

Actuated valves play a crucial role in various industrial processes by regulating the flow of fluids in piping systems. They combine a valve with an actuator, which provides automatic control over the valve’s position and operation. This integration allows for more efficient management of systems that require precise flow and pressure control.

What Are Actuated Valves?

An actuated valve consists of two main components the valve itself and the actuator. The valve is responsible for controlling the flow of steam, gas, or liquid, while the actuator is the device that physically opens or closes the valve. Actuators can be powered by various sources, including electric, pneumatic, or hydraulic energy, allowing for flexibility in different operational environments.

1. Types of Actuators - Electric Actuators These use electric motors to turn gears, which in turn open or close the valve. They are ideal for applications requiring precise positioning and are often used in environments where plumbing air pressures are unsuitable. - Pneumatic Actuators Utilizing compressed air, pneumatic actuators provide rapid movement and are typically more cost-effective for larger applications. They can open and close valves in seconds, making them suitable for processes that require quick responses. - Hydraulic Actuators These rely on hydraulic fluid to operate. Their strong and robust nature makes them ideal for applications that require substantial force to operate the valve.

Key Advantages of Actuated Valves

The integration of actuators into valve systems offers numerous benefits

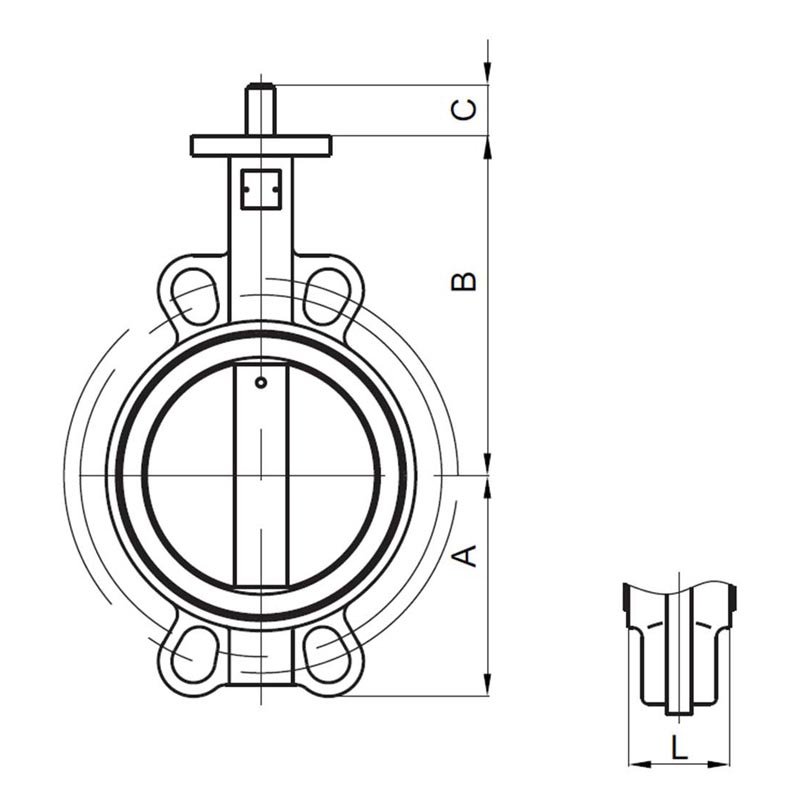

actuated valve

- Enhanced Automation Actuated valves can be integrated into automated control systems, allowing for remote operation and monitoring. This reduces the need for manual labor, minimizes human error, and increases operational efficiency. - Improved Safety By automating valve operations, actuated valves can help prevent accidents caused by human error. They can be programmed to operate in emergency situations without operator intervention, providing an extra layer of safety in critical processes. - Precise Control Automated operation allows for fine-tuning of flow rates and pressure settings, which is essential in various applications, including chemical processes and HVAC systems. - Reduced Maintenance Actuated valves can lead to lower overall maintenance costs by reducing wear and tear associated with manual operation. Systems can be monitored for performance, allowing for predictive maintenance.

Applications of Actuated Valves

Actuated valves can be found in various industries due to their versatility and efficiency. Some common applications include

- Oil and Gas In this sector, actuated valves control the flow of crude oil, natural gas, and other fluids through pipelines. Their ability to operate under high pressures makes them indispensable in offshore and onshore facilities. - Water Treatment Actuated valves are used in the regulation of water and wastewater treatment processes. They manage the flow of water through filtration systems and chemical treatment processes, ensuring compliance with environmental regulations. - Food and Beverage In the food industry, hygiene and precision are paramount. Actuated valves control the flow of ingredients and finished products, ensuring that processes meet strict sanitary guidelines while maintaining efficiency. - Power Generation In power plants, actuated valves manage steam and water flow within turbines and cooling systems, playing a critical role in maintaining system efficiency and safety.

Conclusion

Actuated valves are an integral component of modern industrial operations, offering enhanced automation, improved safety, and precise control over fluid dynamics. As industries continue to evolve, the demand for efficient, reliable, and automated control systems will only increase, making actuated valves a vital area of innovation and development. Understanding their functionality and applications can lead to more efficient and safer industrial processes, ultimately benefiting businesses and consumers alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025