ડીસેમ્બર . 12, 2024 10:35 Back to list

y strainer ansi 150

Understanding Y-Strainers for ANSI 150 Applications

When it comes to maintaining the integrity and efficiency of industrial fluid systems, the importance of filtration cannot be overstated. One essential component that helps achieve this is the Y-strainer. Particularly for systems conforming to ANSI 150 standards, Y-strainers play a critical role in ensuring smooth operation and preventing costly downtimes.

What is a Y-Strainer?

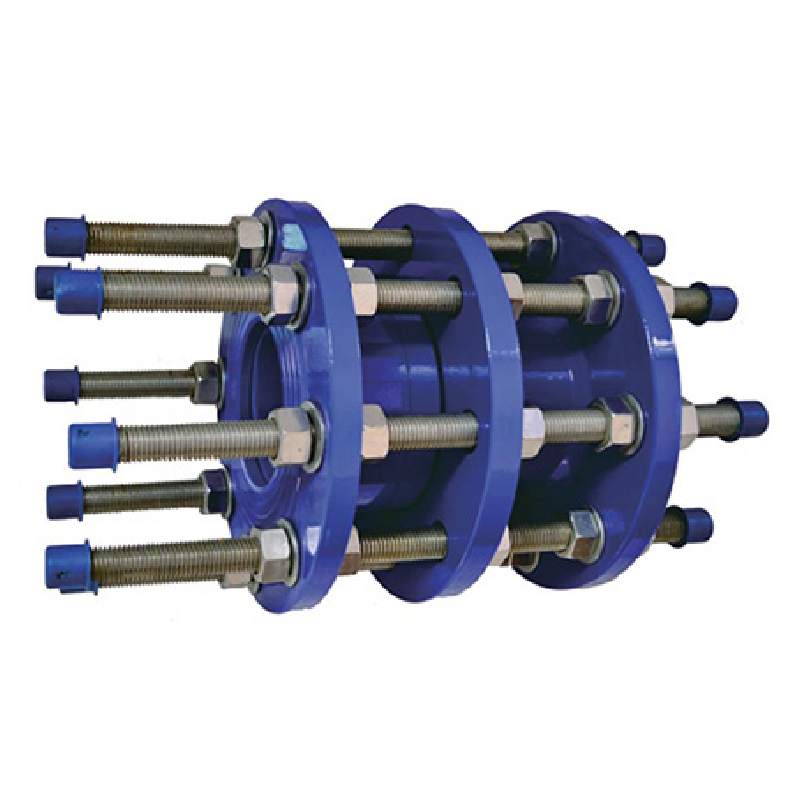

A Y-strainer is a type of mechanical filter used in pipelines to remove debris from liquids or gases. Its distinctive Y shape enhances its capacity to collect and filter out unwanted particles while allowing the flow of the fluid to continue uninterrupted. Y-strainers are designed to be installed in horizontal or vertical pipelines, making them versatile for various applications.

ANSI 150 Standard

The ANSI 150 standard refers to a pressure rating defined by the American National Standards Institute (ANSI) for flanges and fittings in piping systems. This classification indicates a maximum pressure of 150 psi at a specified temperature, making it suitable for many standard industrial applications. Y-strainers designed to meet the ANSI 150 rating ensure reliability and compatibility within systems that use flanges rated for this pressure.

Benefits of Using Y-Strainers

1. Efficient Filtration The primary function of a Y-strainer is to capture solid particles from the fluid. This filtration helps protect downstream equipment, including pumps and valves, ensuring they operate efficiently and reducing wear and tear.

2. Low Maintenance Y-strainers are designed for easy cleaning and maintenance. Many models feature a removable screen or mesh filter that can be quickly accessed to remove accumulated debris without needing to uninstall the entire strainer. This ease of maintenance minimizes downtime and associated costs.

3. Durability Typically constructed from robust materials such as stainless steel or cast iron, Y-strainers can withstand harsh operating conditions, including high pressures and corrosive environments. This durability ensures a long service life, making them a cost-effective choice for industrial applications.

y strainer ansi 150

4. Versatility Y-strainers are suitable for various applications across different industries, including oil and gas, water treatment, chemical manufacturing, and food processing. Their ability to handle different fluid types and conditions makes them a key component in many systems.

5. Safety By preventing contaminants from entering critical system components, Y-strainers enhance the overall safety of industrial operations. Clean fluid systems are less likely to experience failures or accidents due to equipment malfunctions caused by contaminants.

Installation Considerations

Installing a Y-strainer correctly is crucial for its effectiveness. Some key factors to consider include

- Orientation Y-strainers should ideally be installed with the filter element positioned horizontally to maximize debris collection. However, they can also be installed vertically, depending on the application requirements.

- Sizing Proper sizing is critical to ensure that the strainer can handle the expected flow rates without creating excessive pressure drops. It’s essential to consult the manufacturer's guidelines or a qualified engineer to select the appropriate size for your system.

- Location Install the Y-strainer at locations where debris is likely to enter the system, such as downstream of a pump or before critical equipment. Providing easy access for maintenance is also essential for long-term reliability.

Conclusion

In summary, Y-strainers are invaluable tools in maintaining the longevity and efficiency of fluid systems operating under ANSI 150 standards. Their ability to filter out impurities while providing durability and easy maintenance makes them a top choice for engineers and operators alike. By incorporating Y-strainers into your system design, you not only enhance performance but also safeguard against costly operational disruptions. As industries continue to evolve, the role of effective filtration systems, like Y-strainers, will remain a critical focus in ensuring optimal operations and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025