નવેમ્બર . 23, 2024 00:34 Back to list

single plate check valve

The Single Plate Check Valve A Comprehensive Overview

The single plate check valve is a crucial component in various industrial and commercial applications, particularly in fluid and gas systems. Its primary function is to allow flow in one direction while preventing backflow, ensuring the integrity and efficiency of fluid transport systems. Understanding its design, operation, advantages, and applications can greatly enhance effective system management.

Design and Functionality

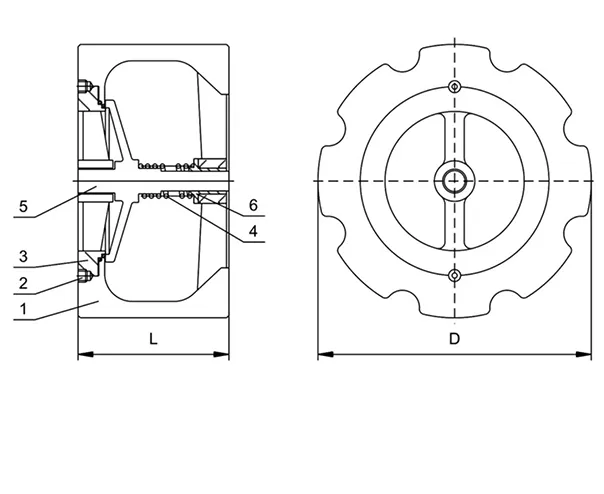

The single plate check valve, often referred to as a swing check valve, comprises a circular disc that pivots on a hinge. This disc is mounted on a frame or body that is securely fastened to the pipeline. When fluid flows in the intended direction, the disc swings open under the influence of the flow's pressure. However, if the flow reverses, the pressure exerted on the disc causes it to close, thereby preventing backflow.

The key design attributes of a single plate check valve include its simple construction, which allows for easy installation and maintenance. Typically made from durable materials such as stainless steel, brass, or PVC, these valves are suited for various service conditions. Their compact size makes them ideal for installations where space is constrained.

Advantages

The single plate check valve boasts several advantages over other types of check valves. One of its most significant benefits is its low-pressure drop during operation. The streamlined design minimizes turbulence and resistance, allowing for optimal flow rates. This efficiency is especially crucial in large-scale systems, where maintaining pressure and flow rates can be critical for operations.

Moreover, the lightweight nature of a single plate check valve reduces the overall load on piping systems

. This characteristic is particularly beneficial in applications where support structures are minimal. The simplicity of the design also allows for easy maintenance, with many installations requiring only periodic inspections and cleaning.Another noteworthy advantage is its resistance to wear and tear. The materials used in constructing single plate check valves are selected for their durability, ensuring long-term reliability in various environments, including those exposed to corrosive substances.

single plate check valve

Applications

Single plate check valves find applications in a wide array of industries. In water and wastewater management, they are essential for controlling flow in treatment facilities and municipal systems, preventing contamination from backflow. The oil and gas sector also utilizes these valves to maintain the integrity of pipelines, ensuring that product flow remains unidirectional even under varying pressure conditions.

In HVAC systems, single plate check valves help maintain airflow in heating and cooling systems, thereby optimizing energy efficiency. Additionally, they are commonly used in irrigation systems, pharmaceuticals, and food processing, where cleanliness and reliability are paramount.

Considerations

While single plate check valves offer numerous benefits, there are some considerations to keep in mind. For instance, they may not be suitable for certain high-viscosity fluids or fluids with a high particulate content, as these conditions can impede the proper operation of the disc. Furthermore, the installation orientation is crucial; these valves must be mounted in a horizontal position to function effectively.

Operators must also be aware that, in some situations, backpressure can keep the valve partially open, which may potentially lead to a flow rate that does not meet operational requirements. Thus, monitoring and regular maintenance are essential for ensuring the valve operates at optimal performance.

Conclusion

In summary, the single plate check valve is an essential component in modern fluid systems. With its straightforward design, low-pressure drop characteristics, and versatility across various applications, it plays a vital role in maintaining efficient and reliable operations in numerous industries. Proper understanding and management of its design and functionality can lead to enhanced performance and longevity of fluid transport systems, thereby contributing to the overall efficiency of industrial processes. As technology advances and industries evolve, the importance and applications of the single plate check valve are likely to expand, making it a fundamental topic in flow control discussions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025