ઓક્ટોબર . 18, 2024 12:06 Back to list

Understanding the Functionality and Benefits of Silent Check Valves in Fluid Systems

The Importance of Silent Check Valves in Fluid Systems

In various industrial applications where fluid movement is required, the integrity and efficiency of the fluid system are paramount. One essential component that plays a critical role in ensuring smooth operation is the check valve. Among these, silent check valves have gained significant attention due to their unique design and functional advantages. This article delves into the features, benefits, and applications of silent check valves, highlighting their importance in modern fluid systems.

What is a Silent Check Valve?

A silent check valve is a type of one-way valve that is designed to allow fluid flow in one direction while preventing backflow. Unlike traditional check valves that can generate noise and hydraulic shock during operation, silent check valves are engineered to minimize these concerns. This design typically involves a unique disc mechanism and a streamlined flow path, enabling smooth operation even at high flow rates.

Design and Functionality

The design of silent check valves is crucial to their performance. These valves typically incorporate a spring mechanism that allows the disc to open and close smoothly. When fluid flows through the valve in the intended direction, the pressure lifts the disc, allowing flow. When the flow reverses, the disc closes, preventing backflow and possible damage to the system.

One of the most notable features of silent check valves is their ability to reduce water hammer—a phenomenon that occurs when fluid flow is suddenly stopped or changed

. This can lead to shock waves in the piping system, causing noise and potentially damaging components. The design of silent check valves effectively absorbs these shock waves, contributing to a quieter and more stable system environment.Benefits of Silent Check Valves

1. Noise Reduction As their name suggests, silent check valves operate quietly. This is particularly important in facilities where noise levels are a concern, such as hospitals, laboratories, and residential buildings. The reduced noise levels contribute to a more pleasant working or living environment.

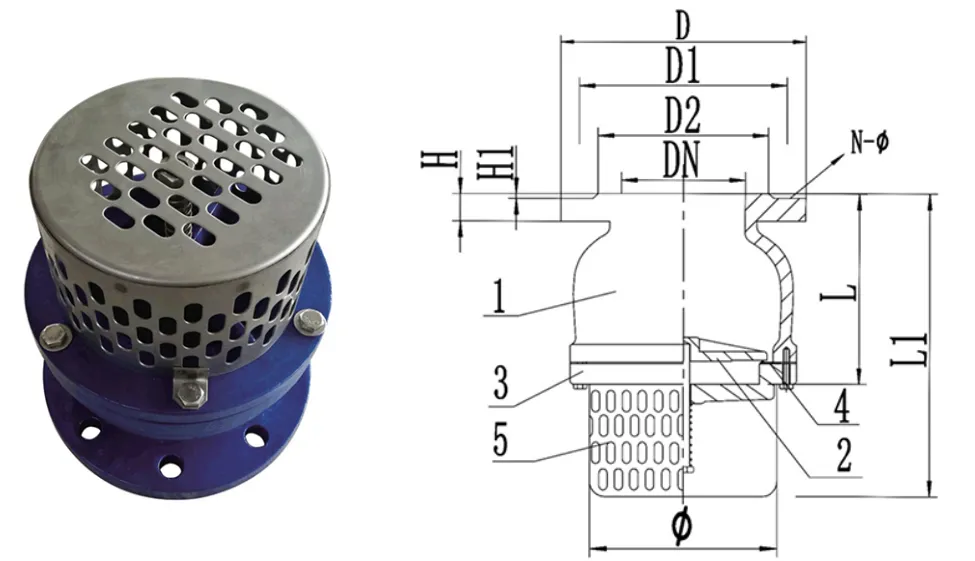

silent check valve

2. Prevention of Backflow Silent check valves provide reliable prevention of backflow, which is critical for maintaining system integrity. Reverse flow can lead to contamination, equipment damage, and other operational issues. The effective sealing capability of these valves ensures that fluids flow in one direction only.

3. Enhanced Performance Due to their efficient design, silent check valves can handle higher flow rates with minimal pressure drop. This means that systems can operate more effectively, leading to energy savings and reduced operational costs.

4. Versatility Silent check valves are suitable for a wide range of applications, including water supply systems, heating and cooling systems, and chemical processing. Their ability to handle various fluids—be it water, steam, or corrosive chemicals—makes them a versatile choice for many industries.

5. Longevity The construction and material choices for silent check valves are typically robust, allowing them to withstand challenging operating conditions. This durability translates to a longer lifespan, reducing the need for frequent repairs or replacements.

Applications

Silent check valves are commonly used in various applications

- Water Supply Systems Ensuring reliable flow and preventing contamination in potable water systems. - HVAC Systems Protecting equipment and maintaining system efficiency. - Industrial Processes Safeguarding against backflow in chemical and manufacturing operations. - Fire Protection Systems Ensuring effective operation of fire suppression systems by preventing backflow.

Conclusion

Silent check valves represent an essential component in modern fluid systems, offering a range of benefits from noise reduction to reliable backflow prevention. Their advanced design and functionality make them indispensable in various industries, enhancing system performance while contributing to a safer and quieter operational environment. As fluid dynamics continue to evolve, the role of silent check valves will undoubtedly become even more critical in ensuring efficient and reliable fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025