ડીસેમ્બર . 11, 2024 06:38 Back to list

Understanding the Functionality and Benefits of Double Swing Check Valves in Piping Systems

Understanding Double Swing Check Valves Functionality and Applications

Check valves are critical components in piping systems, designed to prevent backflow and ensure the unidirectional flow of fluids. Among the various types of check valves, the double swing check valve stands out due to its unique design and functionality. This article explores the features, advantages, applications, and maintenance of double swing check valves.

What is a Double Swing Check Valve?

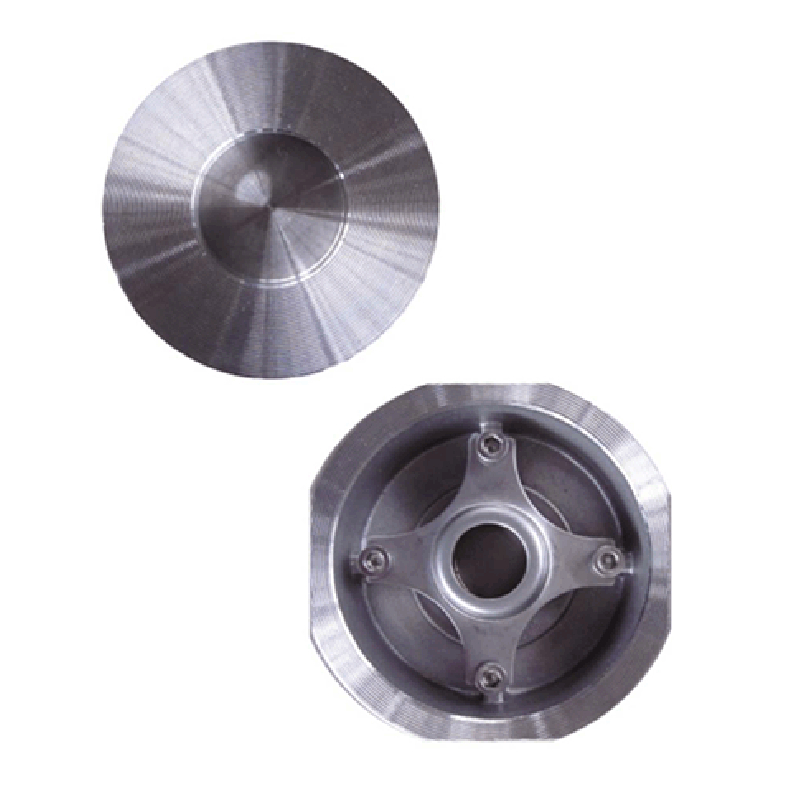

A double swing check valve is a type of valve that utilizes two hinged discs to act as flappers that close when there’s a reverse flow of fluid. Unlike single disc check valves, which pivot on one axis, double swing check valves utilize two discs that can swing simultaneously. This design allows for a larger flow area, reduced pressure loss, and efficient operation. The dual discs create a more stable closure mechanism that can effectively manage high flow rates and turbulent conditions.

Features of Double Swing Check Valves

1. Construction Materials Double swing check valves are available in various materials such as ductile iron, stainless steel, and plastic, allowing them to be used in a wide range of environments, from wastewater treatment to high-temperature industrial applications.

2. Size and Ratings These valves come in a variety of sizes and pressure ratings, accommodating different pipe diameters and operating conditions. Typical sizes range from 2 inches to 24 inches in diameter.

3. Design Flexibility The design allows for the installation in horizontal and vertical piping systems. However, they are often installed horizontally to ensure optimal functionality.

4. Reduces Water Hammer The double swing mechanism helps to minimize the water hammer effect, which is a common problem in piping systems when valves close suddenly.

Advantages of Double Swing Check Valves

1. Enhanced Flow Characteristics The dual disc design facilitates higher flow rates while minimizing pressure drops. This efficiency is crucial in applications requiring high throughput.

2. Improved Reliability With their robust construction and design, double swing check valves are less prone to jamming or malfunctioning than some other check valve types.

double swing check valve

4. Cost-Effective Solution Although the initial investment may be higher than other types of check valves, their durability and reliability lead to lower maintenance costs over time.

Applications of Double Swing Check Valves

1. Water and Wastewater Treatment These valves are often used in treatment plants to prevent backflow into tanks and pipelines.

2. Pumping Stations In pumping systems, double swing check valves prevent reverse flow that can damage pumps and other equipment.

3. Hydraulic Systems They are used to control the direction of fluid flow, ensuring efficiency and safety in hydraulic applications.

4. Industrial Processes Many industries, including oil and gas, food and beverage, and pharmaceuticals, use double swing check valves to ensure the safe and efficient transport of fluids.

Maintenance and Care

To ensure optimal performance and longevity, regular maintenance of double swing check valves is essential. Key maintenance practices include

- Inspection Periodically inspect the valves for signs of wear, corrosion, or sediment buildup that could affect functionality. - Cleaning Regular cleaning of the valve seat and discs helps remove debris that may cause backflow issues.

- Testing Conduct functional tests to ensure that the valves close properly and do not leak under pressure.

Conclusion

Double swing check valves play a vital role in various industries by ensuring the unidirectional flow of fluids and preventing backflow. Their unique design and advantages make them an excellent choice for many applications. Understanding their functionality, proper maintenance, and application can greatly enhance the efficiency and safety of fluid transport systems. As industries continue to evolve, the role of double swing check valves is likely to become even more significant in maintaining operational integrity.

Share