ઓક્ટોબર . 31, 2024 05:47 Back to list

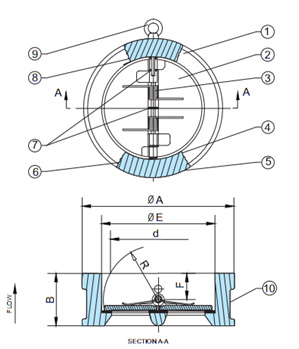

ball valve with y strainer

The Importance of Ball Valves with Y Strainers in Fluid Systems

In the world of fluid dynamics and piping systems, the integration of effective components is crucial for ensuring operational efficiency and reliability. One such dynamic duo is the combination of ball valves and Y strainers. These two components together create a robust solution for managing flow while maintaining system integrity across various applications.

Understanding Ball Valves

Ball valves are renowned for their simplicity and efficiency. They consist of a spherical disc, or ball, which has a hole in the center. This design allows for smooth and quick flow control. When the valve handle is turned, the ball rotates, aligning the hole with the flow path to either open or close the valve. This rapid response time is essential in systems where quick shutoff is necessary, making ball valves a preferred choice in many industries including water treatment, oil and gas, and chemical processing.

The durability and low-pressure drop characteristics of ball valves also contribute to their popularity

. They are capable of handling high-pressure applications and can effectively manage critical conditions without significant wear or failure.The Role of Y Strainers

ball valve with y strainer

Y strainers are devices used to filter out unwanted debris and sediment from fluid systems. Their design resembles the letter “Y,” which allows for easy installation within a pipeline. By trapping solid particles in the mesh screen, Y strainers prevent contaminants from entering downstream equipment, which can lead to fouling, reduced efficiency, and expensive repairs.

Combining Y strainers with ball valves enhances system protection. Installing a Y strainer upstream from a ball valve ensures that only clean fluid is allowed to pass through. As a result, the ball valve can operate without obstruction or damage caused by particulate matter, thus prolonging its lifespan and maintaining optimal performance.

Operational Advantages

The integration of ball valves with Y strainers leads to several operational advantages. Firstly, the overall efficiency of the system is improved, as clean fluid flow minimizes the risk of clogs and pressure drops. Secondly, the combined systems reduce maintenance costs by preventing equipment damage that may arise from unfiltered debris. Lastly, this setup enhances reliability; operators can trust that the system will function smoothly and without unexpected interruptions.

Conclusion

In conclusion, the combination of ball valves and Y strainers presents a practical solution for fluid management in various industries. Their synergy not only optimizes flow control but also enhances the longevity and reliability of piping systems. Engineers and operators alike should consider integrating these components to ensure efficient and trouble-free operations in their fluid handling systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025