Out . 10, 2024 16:38 Back to list

Efficient Production of Swing Check Valves in Our State-of-the-Art Facility

Swing Check Valve Factory Ensuring Reliability in Fluid Control

In the realm of industrial fluid management, the importance of reliable valves cannot be overstated. Among these, swing check valves play a pivotal role in maintaining efficient flow control and preventing backflow, making them indispensable in various applications. A swing check valve factory specializes in the design, production, and distribution of these essential components, ensuring that industries have access to quality products that meet their operational needs.

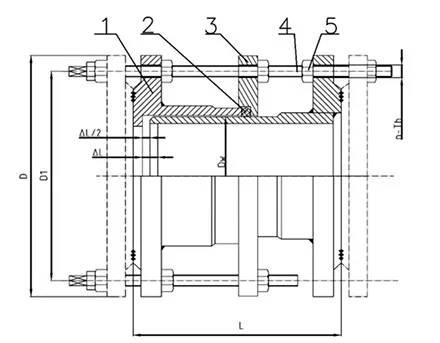

Swing check valves operate on a simple yet effective mechanism. They consist of a disc that swings on a hinge, allowing fluid to flow in one direction while automatically closing to prevent reverse flow. This design minimizes pressure loss and prevents contamination, making swing check valves ideal for water, oil, and gas pipelines. Their reliability is crucial in sectors such as municipal water supply, wastewater treatment, and oil and gas extraction, where backflow can lead to significant operational challenges and safety concerns.

A well-established swing check valve factory employs advanced manufacturing techniques to produce high-quality valves that meet international standards. The production process typically begins with the selection of durable materials, such as stainless steel, cast iron, or brass, depending on the specific application and environmental conditions. These materials are chosen for their strength, resistance to corrosion, and ability to withstand high pressures. The factory utilizes state-of-the-art machinery to ensure precise machining and assembly, which is essential for the valves to function effectively.

swing check valve factory

Quality control is a critical aspect of operations in a swing check valve factory. Each batch of valves undergoes stringent testing to verify that they meet the required performance specifications. This includes pressure testing, flow testing, and operational checks to ensure that the valves can handle their intended pressures and flow rates without failure. By adhering to rigorous quality assurance protocols, the factory ensures that customers receive reliable and long-lasting products.

Moreover, a reputable swing check valve factory stays abreast of technological advancements in valve design and manufacturing processes. Innovations such as CAD modeling and automated assembly lines improve efficiency and accuracy, enabling the factory to respond to market demands swiftly. Additionally, addressing industry trends, such as the increased focus on sustainability, allows the factory to develop eco-friendly solutions that reduce environmental impact without compromising performance.

Collaboration with customers is another key factor for success in a swing check valve factory. Understanding the specific needs of diverse industries allows the factory to provide tailored solutions, ensuring that each client receives a product that fits their operational requirements. Furthermore, offering exceptional customer support and after-sales services builds lasting relationships and fosters brand loyalty.

In conclusion, a swing check valve factory is integral to the fluid control industry, producing valves that ensure operational efficiency and safety across various applications. Through quality manufacturing, innovation, and customer-focused strategies, these factories play a crucial role in advancing fluid management solutions globally.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025