Sult . 22, 2024 19:56 Back to list

ss ball valve

Understanding SS Ball Valves A Key Component in Fluid Control

Stainless steel (SS) ball valves are essential components in various industries for controlling fluid flow. As a type of quarter-turn valve, the SS ball valve uses a spherical disc, known as a ball, to start or stop the flow of fluid. Its reliability, durability, and ease of use make it a popular choice in both residential and industrial applications.

Construction and Material

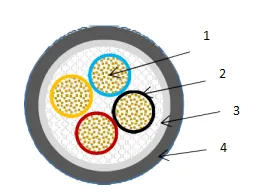

The primary material of SS ball valves is stainless steel, which offers excellent resistance to corrosion and oxidation. This makes them suitable for use in harsh environments where exposure to moisture and chemicals is a concern. The construction typically consists of a ball, a valve body, two end connections, and a stem. The ball has a hole through its center that aligns with the flow when the valve is open and is perpendicular to the flow when closed.

Types of SS Ball Valves

There are several types of stainless steel ball valves available on the market, including

1. Floating Ball Valves In this design, the ball is free to move slightly, allowing it to seal against the downstream seat when the valve is closed. This design is commonly used for applications with lower pressure and is favored for its simplicity and cost-effectiveness.

2. Trunnion Ball Valves These valves have a ball that is anchored by a set of trunnions, providing additional support. This design is ideal for high-pressure applications, as it can handle larger amounts of pressure and provide enhanced sealing capabilities.

3. Electric and Pneumatic Actuated Ball Valves These valves can be automated using either electric or pneumatic actuators, enabling remote control and improving workflow efficiency in industrial settings.

Benefits of SS Ball Valves

ss ball valve

1. Durability The stainless steel material ensures a long lifespan, even in challenging environments. It can withstand high temperatures and pressures, making it reliable for various applications.

2. Sealing Performance SS ball valves offer excellent sealing performance, reducing the risk of leaks. Their design allows for minimal internal friction and more efficient operation compared to other types of valves.

3. Quick Operation The quarter-turn operation of ball valves makes them quick to open and close, allowing for precise control of fluid flow without extensive delay.

4. Versatility These valves can be used in a wide range of applications, from oil and gas extraction to food processing and water treatment. They are suitable for both non-corrosive and corrosive fluids, making them incredibly versatile.

Applications

SS ball valves find applications in numerous fields, including

- Oil and Gas For controlling flow in pipelines and processing plants. - Water Treatment To manage the distribution of water and chemicals. - Chemical Manufacturing In processes that require precise control over corrosive fluids. - Food and Beverage Ensuring hygiene and safety in food processing environments.

Conclusion

In summary, SS ball valves are indispensable in fluid control systems due to their durability, reliability, and efficiency. With various designs catering to different applications, they stand out as a versatile solution for managing the flow of liquids and gases in industrial and residential settings alike. Investing in quality SS ball valves can enhance operational efficiency and ensure safety in fluid handling processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025