Dùbh . 31, 2024 10:04 Back to list

osy gate valve

Understanding the OSY Gate Valve A Comprehensive Overview

In various industrial applications, controlling the flow of fluids is crucial for operational efficiency and safety. One of the key components that assist in this task is the gate valve. Among the different types of gate valves, the OSY (Outside Screw and Yoke) gate valve is particularly notable for its design and functionality. This article delves into the characteristics, advantages, applications, and maintenance practices associated with the OSY gate valve.

What is an OSY Gate Valve?

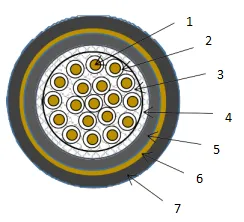

The OSY gate valve is a specific type of gate valve recognized for its unique construction. As the name indicates, the screw mechanism is positioned outside the valve body, which provides several operational advantages. The yoke serves as the frame or support that holds the stem and the disc in place, allowing for a smooth operation of the gate valve.

This type of valve is primarily designed to provide a straight-line flow and minimal resistance to the flow of fluid when fully opened. The OSY gate valve operates by lowering or raising a flat disc positioned within the valve body. When the valve is in the open position, the disc completely retracts into the valve, facilitating unrestricted fluid movement.

Key Features and Advantages

1. Construction Design One of the significant features of an OSY gate valve is its external screw and yoke mechanism. This design not only protects the valve stem from the media being transported but also makes it easier to inspect and maintain the valve.

2. Reliable Operation The OSY gate valve is known for providing a reliable seal, making it suitable for applications where leakage is a concern. When fully closed, the valve ensures that there is no flow, thus preventing any contamination or loss of fluid.

3. Ease of Maintenance Since the screw is located outside the valve body, it simplifies maintenance tasks. Operators can easily access and replace the stem packing without having to disassemble the entire valve, reducing downtime and maintenance costs.

4. Robustness OSY gate valves are typically constructed from durable materials, including cast iron, stainless steel, and bronze, which ensures longevity and performance in various environments, including high pressure and temperature situations.

5. Versatility These valves are versatile and can be used for various applications, including water supply systems, sewage treatment plants, and in the petrochemical industry. Their ability to function efficiently under different conditions makes them a preferred choice across numerous sectors.

Applications

OSY gate valves are widely utilized in numerous industries due to their robust performance and reliable sealing capabilities

. Common applications includeosy gate valve

- Water Supply Systems In municipal and industrial water systems, OSY gate valves are used to manage the flow of water, ensuring that systems remain operational under various conditions.

- Sewage Treatment In sewage treatment plants, these valves help control the flow of wastewater, contributing to effective waste management and treatment processes.

- Oil and Gas Industry The petroleum industry employs OSY gate valves for their reliability and ability to handle high-pressure environments, thus playing a crucial role in pipeline systems.

- Fire Protection Systems In fire protection systems, OSY gate valves are often used to control the supply of water to fire sprinkler systems, providing a vital safety feature in buildings.

Maintenance Best Practices

For the OSY gate valve to perform optimally, regular maintenance is essential. Here are some best practices

1. Routine Inspections Regular inspections can help identify wear and tear or leaks before they become major issues. Check the valve for rust, corrosion, or any mechanical damage.

2. Lubrication The external screw mechanism should be properly lubricated to ensure smooth operation. Regular lubrication reduces friction and wear on components.

3. Replacement of Packing Over time, the packing can become worn. Regularly inspect the packing for leaks and replace it as necessary to maintain an effective seal.

4. Operational Checks Perform periodic operational tests to confirm that the valve opens and closes properly, ensuring that it can handle pressures expected in its application.

Conclusion

The OSY gate valve is a crucial component in many industrial systems, offering robust performance, reliability, and ease of maintenance. Its unique design ensures effective fluid control, making it a preferred choice across a range of industries. By adhering to proper maintenance practices, operators can enhance the lifespan and performance of these valves, ensuring they continue to contribute effectively to the systems in which they are installed. Understanding the characteristics and advantages of OSY gate valves is essential for anyone involved in industrial operations, as it equips them with the knowledge to make informed decisions regarding fluid control systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025