Samh . 08, 2024 01:32 Back to list

Industrial Water Control Valve Solutions for Efficient Water Management Systems

Understanding Industrial Water Valves Their Importance and Functionality

In various industrial applications, water is often a critical resource, utilized for cooling, processing, and waste management. To ensure the efficacious management of water resources, industrial water valves play an essential role. These valves, designed specifically for high-demand environments, regulate the flow and pressure of water within industrial systems, making them pivotal for operational efficiency and safety.

What Are Industrial Water Valves?

Industrial water valves are mechanical devices that control the passage of water within pipelines and systems in industrial settings. They can either stop or allow the fluid to flow through pipes, tanks, and other equipment. These valves vary in design, size, and functionality, and they are manufactured from different materials to accommodate diverse requirements, including stainless steel, brass, and plastic.

Types of Industrial Water Valves

There are several types of industrial water valves, each designed for specific applications

1. Gate Valves Often used for on/off control, gate valves create a straight-through flow and are typically employed in situations where minimal pressure drop is desired. They are not recommended for throttling purposes.

2. Globe Valves Unlike gate valves, globe valves are designed for throttling. They provide good control over flow and pressure, making them suitable for applications where precise regulation is required.

3. Ball Valves Featuring a spherical disc that controls flow, ball valves are known for their durability and easy operation. They are commonly used in situations requiring a quick shut-off.

4. Check Valves These valves ensure that water flows in one direction only, preventing backflow and maintaining system efficiency. They are crucial in systems where reverse flow could cause damage.

5. Butterfly Valves With a circular disc that can be turned to regulate flow, butterfly valves offer a compact and lightweight solution for flow control.

Importance of Industrial Water Valves

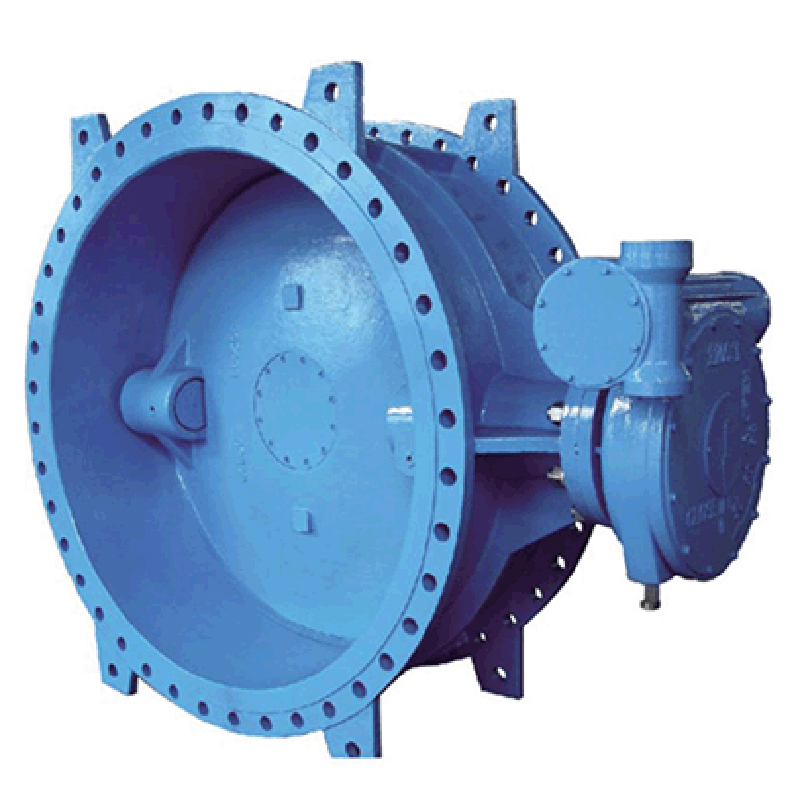

industrial water valve

The significance of industrial water valves cannot be overstated. They offer numerous benefits, including

- Flow Regulation By controlling the flow of water, these valves help maintain the desired levels required for industrial processes. This regulation is crucial for cooling systems, chemical processing, and agricultural irrigation.

- Safety Industrial water valves contribute to system safety by preventing overpressure scenarios and leaks. Regular maintenance and proper functioning of these valves are vital to avoid catastrophic failures.

- Energy Efficiency Properly functioning valves reduce energy consumption by optimizing water flow and minimizing losses. This efficiency contributes to lower operational costs and a reduced environmental footprint.

- Versatility With a range of designs and functionalities, industrial water valves can be used in various applications across multiple industries, including manufacturing, agriculture, mining, and water treatment facilities.

Maintenance of Industrial Water Valves

For optimal operation, regular maintenance of industrial water valves is essential. Key maintenance practices include

- Regular Inspections Check for signs of wear, corrosion, or damage. Early detection can prevent more severe issues down the line.

- Lubrication Proper lubrication of moving components ensures smooth operation and prevents sticking and malfunctioning.

- Testing Periodically testing valves to ensure they open and close properly is crucial in identifying potential issues before they escalate.

Conclusion

In conclusion, industrial water valves are integral to maintaining the efficiency and safety of water management systems in industrial settings. By controlling the flow and pressure of water, these valves play a vital role in ensuring operational effectiveness across various applications. Understanding the types of valves available and their specific functions can empower industries to make informed decisions about their water management strategies. Regular maintenance is key to prolonging the life and functionality of these essential devices, ultimately leading to safer and more efficient industrial operations.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025