Samh . 07, 2024 17:30 Back to list

Comprehensive Guide to Industrial Gate Valve Applications and Benefits in Various Industries

Understanding Industrial Gate Valves A Comprehensive Overview

Gate valves are a crucial component in various industrial applications, providing a reliable means of controlling fluid flow. Specifically designed for on/off service, these valves are typically used in scenarios where minimal flow restriction is essential when the valve is fully open. Industrial gate valves are found in numerous sectors, including oil and gas, water treatment, chemical processing, and power generation. This article will delve into the design, functionality, advantages, and considerations surrounding industrial gate valves.

Design and Functionality

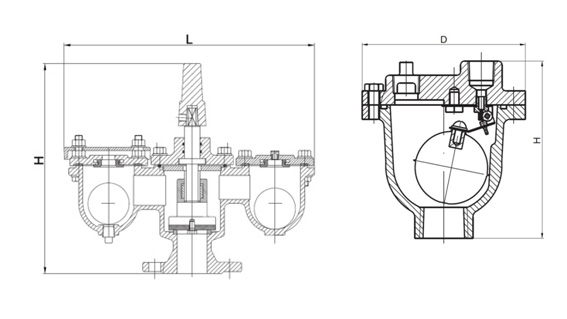

Industrial gate valves consist of a few key components the body, gate, bonnet, seat, and actuator. The body is typically made from durable materials such as cast iron, stainless steel, or carbon steel to withstand high pressure and corrosive environments. The gate, often shaped like a wedge, is designed to lift or lower to regulate flow. When the gate is fully open, there is a straight flow path, allowing for minimal turbulence and resistance.

The operation of a gate valve is straightforward. When the actuator (manual or automated) is turned, the gate is raised from the seat, allowing fluid to flow through the valve. Conversely, turning the actuator in the opposite direction lowers the gate into the seat, effectively blocking flow. This design ensures that when the valve is fully open, it does not impede the flow of fluid, making gate valves ideal for applications requiring a straight-line flow.

Advantages of Industrial Gate Valves

One of the primary advantages of gate valves is their ability to provide a tight seal when closed. This is essential in preventing leaks and maintaining system integrity, especially in high-stakes industrial environments. Additionally, gate valves offer low flow resistance when fully open, which helps to minimize pressure drops across the valve. This characteristic is particularly beneficial in large pipelines where maintaining pressure is critical for efficient operations.

industrial gate valve

Another significant advantage is their durability and longevity. Industrial gate valves are constructed from robust materials designed to withstand harsh operating conditions, including high pressures and corrosive fluids. When properly maintained, these valves can last for many years, contributing to cost savings and reduced downtime.

Considerations in Using Gate Valves

While gate valves come with several advantages, there are some considerations to keep in mind. First, they are not suitable for throttling applications. Attempting to partially open a gate valve can lead to vibration, noise, and potential damage to the valve. Therefore, their primary function should be confined to fully open or fully closed positions.

Additionally, gate valves may require more space to operate compared to other valve types, such as globe valves. This can be a limiting factor in applications where space is at a premium. Furthermore, the actuation mechanism may require regular maintenance to ensure smooth operation, especially in automated systems.

Conclusion

In summary, industrial gate valves play an essential role in fluid control across various industries. Their design allows for minimal flow resistance, a robust sealing ability, and exceptional durability, making them a preferred choice for many applications. However, it is crucial to understand their limitations and operational requirements to optimize their use effectively. As industries continue to evolve, the demand for reliable and efficient flow control solutions, like industrial gate valves, will persist, ensuring their ongoing relevance in the industrial landscape.

Share