Dùbh . 24, 2024 17:27 Back to list

cast steel valve

The Importance of Cast Steel Valves in Modern Industry

In the realm of industrial applications, the significance of cast steel valves cannot be overstated. Cast steel valves are pivotal components in a wide array of systems, ranging from water supply and sewage treatment to the oil and gas industry. These valves serve crucial functions, including controlling the flow of fluids, regulating pressure, and ensuring the safe operation of various processes. This article delves into the construction, benefits, and applications of cast steel valves, underscoring their critical role in modern industry.

Construction and Material Properties

Cast steel, an iron-carbon alloy, is known for its excellent strength, durability, and resistance to wear and tear. The casting process allows for the creation of complex shapes, making it an ideal material for valve manufacturing. The casting of steel also results in a non-porous structure, which significantly reduces the likelihood of leaks, a vital attribute when dealing with high-pressure systems.

Cast steel valves are typically manufactured using a variety of grades, including ASTM A216 WCB (Wrought Carbon Steel) and ASTM A352 LCB (Low Temperature Carbon Steel), among others. The choice of material depends on the specific application requirements, including temperature, pressure, and corrosive conditions. The versatility of cast steel allows these valves to be tailored for a wide spectrum of industries, thus meeting diverse operational needs.

Advantages of Cast Steel Valves

1. Durability and Strength One of the most significant benefits of cast steel valves is their high durability. Due to the inherent strength of steel, these valves can withstand extreme temperatures and pressures without compromising their integrity. This feature is particularly important in industries where safety and reliability are paramount.

2. Corrosion Resistance While cast steel is susceptible to corrosion in harsh environments, advancements in surface treatment technologies, such as galvanizing and coating, have enhanced their resistance to corrosive substances. This makes cast steel valves suitable for various applications, including those involving chemicals and liquids.

3. Cost-Effectiveness Though the initial investment in cast steel valves may be higher compared to other materials like plastic or brass, the long-term benefits often outweigh the costs. Their durability translates to less frequent replacements and lower maintenance costs over time.

cast steel valve

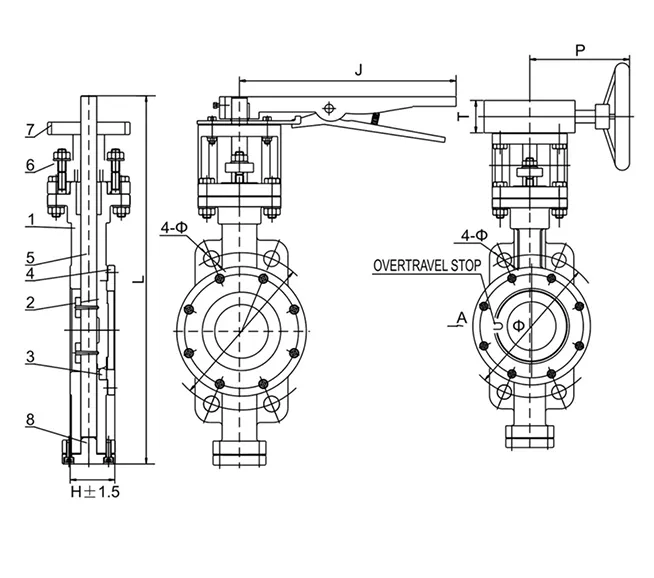

4. Versatility Cast steel valves come in various designs such as gate, globe, ball, and check valves, making them adaptable for numerous applications. They can be used in conditions ranging from low to high pressure, further broadening their usability across different sectors.

Applications in Various Industries

The versatility of cast steel valves enables their use in numerous industries

- Oil and Gas In the oil and gas sector, cast steel valves are vital for controlling the flow of crude oil and natural gas. Their robustness ensures safety and operational efficiency in environments characterized by high pressures and corrosive substances.

- Water Supply and Wastewater Treatment cast steel valves play a significant role in managing water distribution systems and wastewater treatment facilities. They help regulate flow, manage pressure, and minimize leakage, thereby enhancing system efficiency.

- Power Generation These valves are also essential in power plants, especially in steam and hydroelectric facilities. The ability of cast steel valves to withstand high temperatures and pressures makes them suitable for turbine control.

- Chemical Processing In the chemical industry, where processes often involve corrosive materials, cast steel valves can be treated to resist chemical degradation, ensuring both safety and reliability.

In conclusion, cast steel valves are integral components of modern industrial systems. Their durability, strength, and versatility make them an optimal choice for a wide range of applications. As industries continue to evolve, the reliance on advanced materials like cast steel will grow, solidifying the status of cast steel valves as indispensable tools in ensuring efficiency, safety, and sustainability in industrial processes.

Share