Samh . 27, 2024 10:43 Back to list

Double Flange Butterfly Valve Design and Applications for Efficient Flow Control

The Butterfly Valve Double Flange Type Explained

In various industrial applications, valves play a crucial role in controlling the flow of liquids and gases. Among the many types of valves available, the butterfly valve, particularly the double flange type, stands out due to its versatility and efficiency. This article aims to provide an in-depth look at the butterfly valve with a focus on its double flange design, applications, advantages, and maintenance considerations.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn rotational motion valve that is generally used to regulate or isolate flow. It consists of a circular disc or vane that rotates around a central axis to either allow or block fluid passage. The simplicity of its design allows for quick operation and minimal pressure drop, making it an efficient choice for various systems.

Understanding the Double Flange Type

The double flange butterfly valve is designed with flanges on both sides of the valve body. This configuration enables easy installation and removal, as it can be mounted between two flanged pipes. The double flange design is particularly advantageous in applications where space is a constraint, as it reduces the need for additional supports or fittings.

One of the primary features of the double flange type is its ability to maintain a tight seal. This is achieved through the use of high-quality seals and gaskets, ensuring that the valve can effectively isolate sections of the pipeline when closed. In high-pressure applications, this ability to maintain integrity is critical.

Applications

The double flange butterfly valve is used across various industries including water management, oil and gas, chemical processing, and HVAC systems. In water treatment facilities, for example, these valves control the flow of water between treatment and distribution systems. In the oil and gas sector, they are often employed to manage the transport of hydrocarbons and gases.

Moreover, the double flange design is favored in systems that require regular maintenance, as it facilitates easy access to the valve's internal components. This is particularly important in industries where routine inspections and replacements are necessary to ensure system reliability and safety.

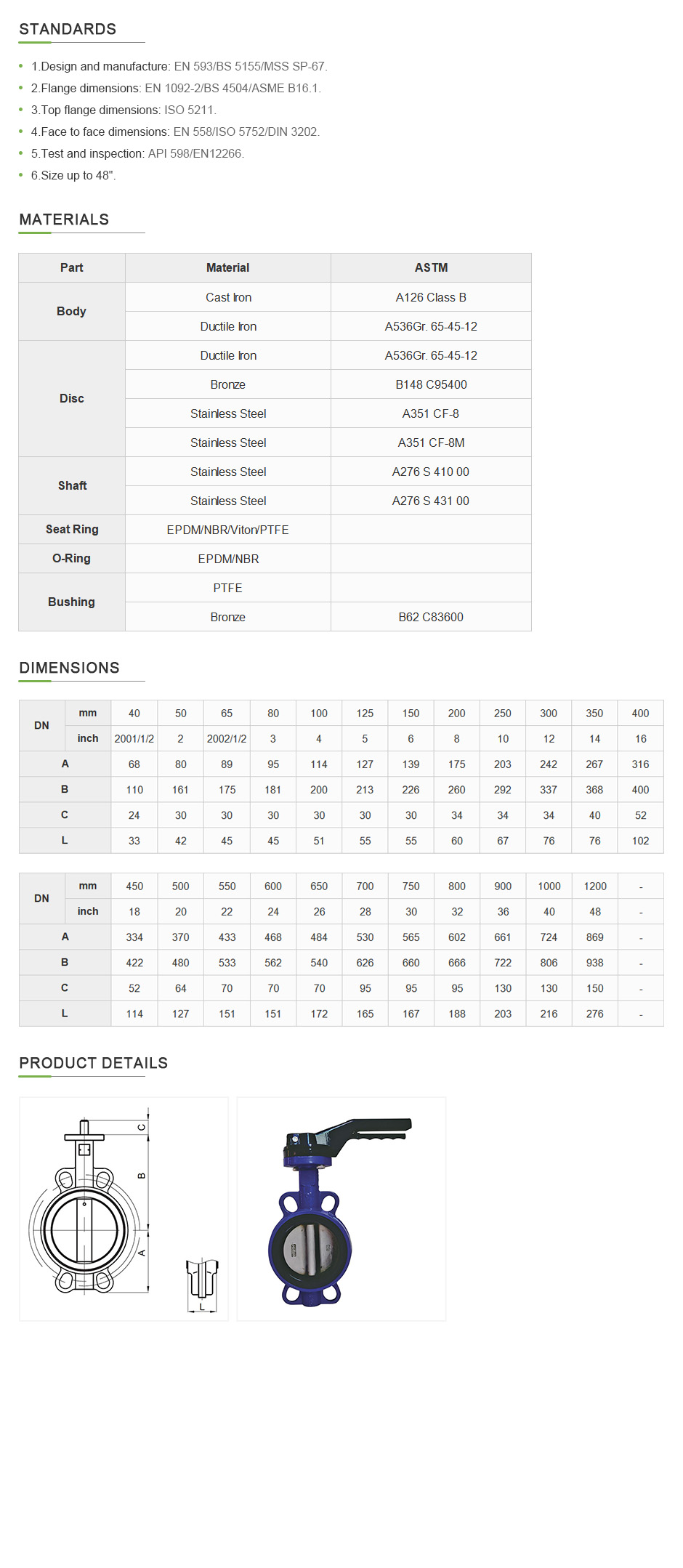

butterfly valve double flange type

Advantages of Double Flange Butterfly Valves

1. Compact Design Compared to other types of valves, butterfly valves are relatively lightweight and occupy less space, making them easier to install in confined areas.

2. Cost-Effective The manufacturing and installation costs of butterfly valves are generally lower than those of gate or globe valves, providing an economical solution for flow control.

3. Quick Operation The quarter-turn mechanism allows for rapid opening and closing, which is essential in applications requiring swift response times.

4. Low Pressure Drop Butterfly valves typically have lower pressure drops compared to other valve types, contributing to energy efficiency in fluid systems.

5. Easy Maintenance The double flange design not only aids in installation but also serves to simplify maintenance operations, reducing downtime.

Maintenance Considerations

While double flange butterfly valves are designed for durability, regular maintenance is essential to ensure optimal performance. Operators should regularly inspect the valve for signs of wear or damage, including checking seals and gaskets for deterioration. Additionally, operators should ensure that the actuator functions correctly and that the valve opens and closes smoothly.

In summary, the double flange butterfly valve is an essential component in fluid control systems across numerous industries. Its compact design, efficiency, and ease of maintenance make it a popular choice for engineers and operators alike. Understanding the functionalities and applications of this valve type is vital for maximizing operational efficiency and safety in pipeline systems. As industries continue to evolve, the demand for reliable and effective valves like the double flange butterfly valve will undoubtedly grow.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025