Feb . 19, 2025 08:38 Back to list

Dual Plate Check Valve

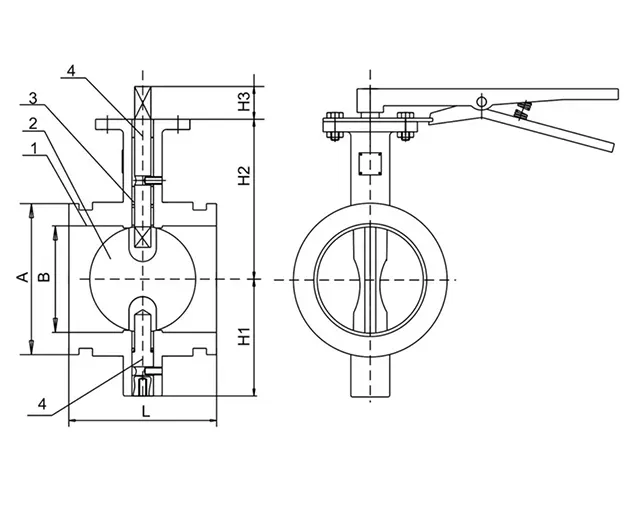

A wafer type butterfly check valve is an engineering marvel designed to streamline flow control in various industrial applications. With a unique blend of design efficiency and performance reliability, this valve is essential in sectors ranging from petrochemicals to water treatment facilities. Each component of this valve has been meticulously engineered, ensuring that what you have is not just a component, but a strategic tool in process systems management. Understanding these valves in terms of experience, expertise, authoritativeness, and trustworthiness can significantly enhance operational efficiency.

Trustworthiness in wafer type butterfly check valves is established through real-world applications and testimonials from industry experts. Industrial operators have consistently reported reduced maintenance needs and extended service life, further cementing the valve’s reputation. The check valve function of preventing reverse flow is crucial in safeguarding pumps and compressors, thus protecting costly equipment from potential damage caused by backflow. Users rely on these valves for their precision in ensuring unidirectional flow, even in complex systems with variable pressures. To maximize the benefits of incorporating wafer type butterfly check valves, selecting the appropriate valve size and type in correlation with the system requirements is vital. Proper sizing and material selection are critical to achieving the desired performance levels and efficiency. Consulting with fluid dynamics specialists can provide deeper insights into specific application requirements, ensuring that the chosen valve meets all operational expectations. Continuing advancements in valve technology mean that manufacturers are constantly improving designs to cater to the growing demands of modern industries. Innovations such as reduced friction components, improved sealing technology, and materials resistant to extreme temperatures and chemical exposure are keeping wafer type butterfly check valves at the forefront of industrial applications. The emphasis on R&D ensures that they remain a reliable choice, matching the pace of technological progress. In conclusion, wafer type butterfly check valves are a valuable asset to any industrial process requiring effective flow regulation and equipment protection. Their sophisticated design, combined with robust material selection and compliance with international standards, marks them as a top choice for engineers and technicians. For industries looking to balance efficiency, reliability, and cost-effectiveness, these valves consistently deliver a competitive edge.

Trustworthiness in wafer type butterfly check valves is established through real-world applications and testimonials from industry experts. Industrial operators have consistently reported reduced maintenance needs and extended service life, further cementing the valve’s reputation. The check valve function of preventing reverse flow is crucial in safeguarding pumps and compressors, thus protecting costly equipment from potential damage caused by backflow. Users rely on these valves for their precision in ensuring unidirectional flow, even in complex systems with variable pressures. To maximize the benefits of incorporating wafer type butterfly check valves, selecting the appropriate valve size and type in correlation with the system requirements is vital. Proper sizing and material selection are critical to achieving the desired performance levels and efficiency. Consulting with fluid dynamics specialists can provide deeper insights into specific application requirements, ensuring that the chosen valve meets all operational expectations. Continuing advancements in valve technology mean that manufacturers are constantly improving designs to cater to the growing demands of modern industries. Innovations such as reduced friction components, improved sealing technology, and materials resistant to extreme temperatures and chemical exposure are keeping wafer type butterfly check valves at the forefront of industrial applications. The emphasis on R&D ensures that they remain a reliable choice, matching the pace of technological progress. In conclusion, wafer type butterfly check valves are a valuable asset to any industrial process requiring effective flow regulation and equipment protection. Their sophisticated design, combined with robust material selection and compliance with international standards, marks them as a top choice for engineers and technicians. For industries looking to balance efficiency, reliability, and cost-effectiveness, these valves consistently deliver a competitive edge.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025