Dec . 16, 2024 09:48 Back to list

Durable Galvanized Rubber Expansion Joint for Enhanced Flexibility and Leak Prevention

The Importance of Galvanized Rubber Expansion Joints in Industrial Applications

In the realm of industrial piping systems, the use of expansion joints is crucial for maintaining system integrity and functionality. Among the various types of expansion joints available, galvanized rubber expansion joints stand out for their unique combination of properties that cater to specific needs within diverse engineering applications. These joints play a pivotal role in absorbing movement, vibration, and thermal expansion, thereby enhancing the operational lifespan of piping systems.

What Are Galvanized Rubber Expansion Joints?

Galvanized rubber expansion joints consist of a rubber body reinforced with metal (often galvanized steel) components. This dual construction allows them to withstand various operational stresses while providing the flexibility necessary to accommodate the thermal expansions and contractions that occur in pipes during their use. The rubber material typically used in these joints is specifically formulated to resist degradation from heat, chemicals, and environmental factors, making it highly effective in industrial settings.

Key Features and Benefits

1. Corrosion Resistance The galvanized steel reinforcement provides excellent resistance to corrosive environments. In industrial applications where pipes carry aggressive fluids, ensuring the longevity of joints is paramount. Galvanization helps protect against rust and wear, extending the life of the expansion joint.

2. Flexibility and Shock Absorption The rubber component of these joints is designed to absorb vibrations caused by machinery and fluid flow. This flexibility allows for the smooth operation of piping systems, preventing stress on pipe connections that could lead to failures or leaks.

3. Thermal Expansion Compensation Galvanized rubber expansion joints can accommodate significant thermal expansion and contraction, which is crucial in applications where temperature fluctuation is common. This adaptability reduces the risk of pipe rupture and other damage caused by thermal stress.

4. Ease of Installation These joints are often easier to install than rigid piping connections, as their flexibility allows for adjustments during installation. This feature can significantly reduce labor costs and installation time during pipe system setups.

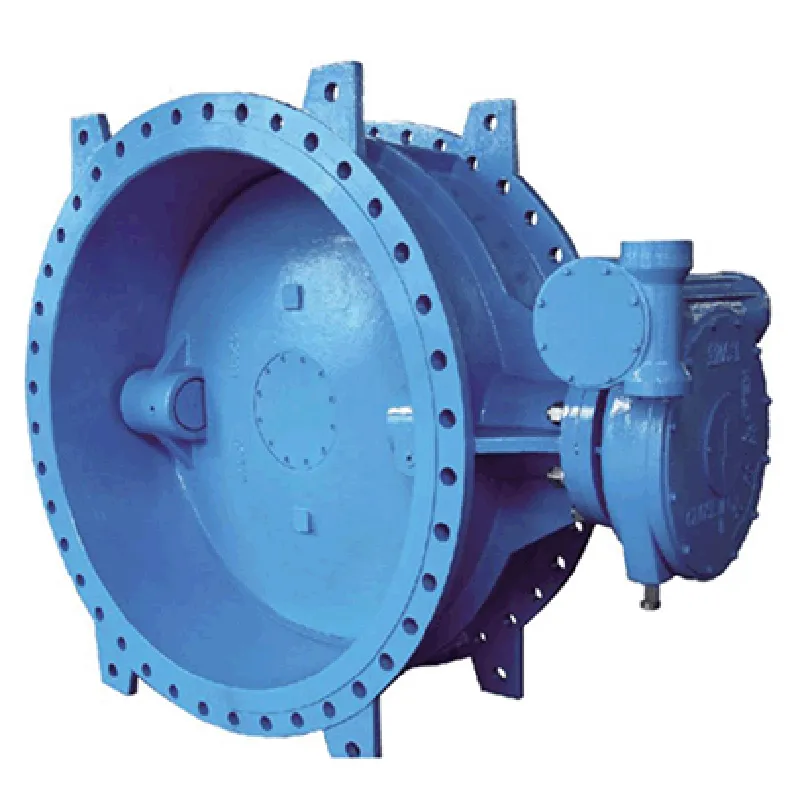

galvanized rubber expansion joint

5. Noise Reduction The rubber material serves as a sound-dampening component, which helps to minimize noise generated by the flow of fluids and vibrations in the piping system. This benefit is particularly relevant in environments where noise control is a priority, such as in residential areas or near sensitive equipment.

Applications of Galvanized Rubber Expansion Joints

The versatility of galvanized rubber expansion joints allows them to be utilized in various industries, including

1. Chemical Processing Due to their resistance to chemicals and corrosive materials, these joints find extensive use in chemical processing plants where aggressive materials are present.

2. Water Treatment In water treatment facilities, expansion joints help manage fluctuations in water temperatures and pressures, ensuring that the systems operate efficiently and without breaking down.

3. HVAC Systems In heating, ventilation, and air conditioning systems, galvanized rubber expansion joints are employed to absorb vibrations from fans and pumps, contributing to a quieter and more efficient operation.

4. Petroleum and Petrochemical Industries These joints are commonly used where hot fluids are transported, as their thermal resistance is favorable in high-temperature applications.

Conclusion

Galvanized rubber expansion joints are essential components in modern industrial applications. Their unique combination of flexibility, strength, and resistance to corrosion makes them an ideal solution for various piping needs. By absorbing thermal expansions, vibrations, and shocks, they not only prolong the life of pipe systems but also ensure safe and efficient operations. As industries continue to innovate and evolve, the significance of reliable, efficient components like galvanized rubber expansion joints will undoubtedly remain paramount for operational success. Investing in quality expansion joints should be a priority for industries looking to enhance the integrity and efficiency of their piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025