Aug . 30, 2024 12:41 Back to list

Flow Control Check Valves - Efficient Flow Management Solutions

Flow Control Check Valves Ensuring Efficient Fluid Management

Flow control check valves play a crucial role in various industrial applications by regulating the direction and flow rate of fluids within a system. These valves are designed to allow fluid to flow in one direction while preventing reverse flow, thereby maintaining system efficiency and integrity. Their significance cannot be overstated, particularly in processes where fluid dynamics and pressure control are paramount.

A check valve operates based on pressure differences; when the pressure in the inlet exceeds that of the outlet, the valve opens, allowing fluid to flow. Conversely, if the outlet pressure rises beyond the inlet, the valve closes, preventing backflow. This mechanism protects equipment from damage caused by reverse flows, such as pump failure or contamination of the supply.

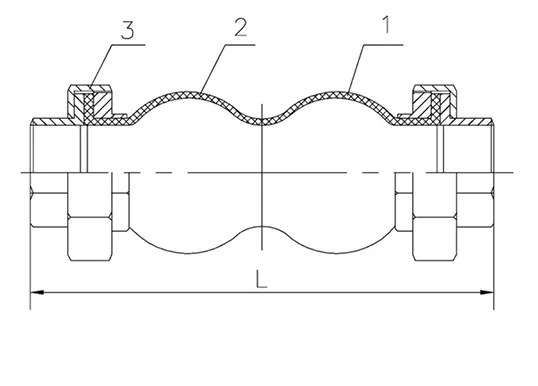

There are various types of check valves, including spring-loaded, swing, and lift check valves, each suited to different applications. Spring-loaded check valves use a spring mechanism to assist the valve closure, making them ideal for high-pressure systems. Swing check valves, on the other hand, feature a disc that swings open with forward flow and closes against the flow, suitable for gravity-driven systems. Lift check valves are appropriate for vertical applications where fluid velocity and backpressure are relatively low.

flow control check valve

The selection of an appropriate check valve depends on several factors, including the type of fluid, the pressure and temperature conditions, and the specific requirements of the system. For instance, in a high-temperature setting, a valve made from stainless steel might be preferable to prevent degradation. In contrast, in corrosive environments, materials like PVC or other plastics may offer better longevity and safety.

Flow control check valves are widely used in various sectors, including water treatment, chemical processing, and HVAC systems. In water treatment plants, these valves are essential in maintaining a consistent flow rate and preventing contamination in the distribution system. Similarly, in chemical processing, they help contain hazardous fluids and prevent backflow, ensuring both safety and operational efficiency. In HVAC systems, check valves regulate the flow of refrigerants, maintaining the correct pressure within the system and enhancing overall performance.

Regular maintenance of flow control check valves is vital to ensure their longevity and performance

. Accumulated debris and sediment can hinder valve operation, leading to inefficiencies and potential system failures. Routine inspections and cleaning are necessary to uphold the system’s integrity and prevent costly downtime.In conclusion, flow control check valves are indispensable components in fluid management systems. Their ability to regulate flow direction and prevent backflow enhances system efficiency, safety, and reliability across numerous applications. Understanding the different types and their suitable applications can aid engineers and technicians in selecting the right valve for their specific needs, ultimately leading to improved operational performance. As industries continue to evolve, the role of flow control check valves will undoubtedly remain significant, ensuring fluid systems function optimally in various operating conditions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025