Aug . 23, 2025 15:55 Werom nei list

The Lifespan of a Typical Dismantling Joint

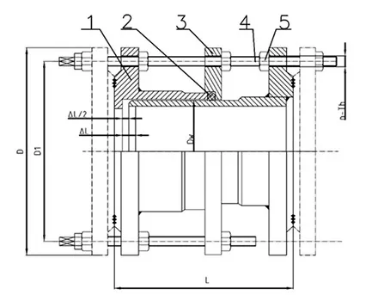

Dismantling joints are unsung heroes in piping systems, enabling easy maintenance, alignment, and repairs without disrupting the entire network. The lifespan of a dismantling joint—whether it’s a pipe dismantling joint or flange dismantling joint—depends on factors like material, usage, and maintenance. 2025 Hebei honest industrial group Co.,Ltd., established in 2006 as a professional manufacturer of middle & low pressure valves with a 15,000-square-meter facility, produces high-quality joints and fittings, including durable dismantling joint models. Their ISO and CE certifications ensure these products meet strict standards, making them a reliable choice for long-term use. This article explores the typical lifespan of dismantling joint products, the factors that influence it, and how to extend their service life.

Factors Affecting Dismantling Joint Lifespan

- Material Quality: The material of a dismantling joint is a primary determinant of its lifespan. 2025 Hebei honest industrial group uses materials like ductile iron, stainless steel, and duplex for their joints. Stainless steel pipe dismantling joint models, for example, resist corrosion and wear, lasting longer in humid or chemical-rich environments than cast iron alternatives, which may degrade faster in harsh conditions.

- Operating Conditions: Piping systems with high pressure, extreme temperatures, or frequent pressure fluctuations put more stress on flange dismantling joint A joint in a low-pressure water system may last 15–20 years, while one in a high-pressure petrochemical pipeline might need replacement after 10–12 years due to increased wear from constant stress.

- Maintenance Practices: Regular inspection and lubrication of dismantling joint parts—like gaskets and bolts—prevent premature failure. Neglecting to replace worn gaskets or tighten loose bolts can lead to leaks, corrosion, and reduced lifespan, sometimes cutting a joint’s service life by half.

Lifespan of Pipe Dismantling Joint

- General Service Life: A well-maintained pipe dismantling joint typically lasts 10–20 years, depending on the material and application. Ductile iron models, common in water distribution systems, often hit the 15–20 year mark thanks to their resistance to rust and moderate pressure. Stainless steel versions, used in industrial settings with corrosive fluids, can last 12–18 years, even with frequent use.

- Signs of Wear to Watch For: Over time, pipe dismantling joint gaskets may harden or crack, leading to leaks. Bolts can also corrode, making disassembly difficult. If you notice leaks around the joint or struggle to loosen bolts during maintenance, it may be time to replace the joint—ignoring these signs can damage adjacent pipes, increasing repair costs.

- Extending Lifespan: Applying food-grade lubricant to bolts annually and replacing gaskets every 5–7 years (sooner in high-use systems) can significantly extend a pipe dismantling joint’s life. Choosing the right material for the fluid type—like stainless steel for chemicals—also prevents unnecessary corrosion.

Flange Dismantling Joint Longevity

|

Factor |

Impact on Flange Dismantling Joint Lifespan |

Average Lifespan Range |

Improvement Tips |

|

Flange Material |

Cast iron flange joints last shorter (8–12 years) than stainless steel (15–20 years). |

8–20 years |

Opt for stainless steel or duplex material for high-pressure, corrosive systems. |

|

Gasket Quality |

Poor-quality gaskets degrade quickly, causing leaks and joint damage. |

N/A (affects overall joint) |

Use EPDM or PTFE gaskets, replacing them every 3–5 years. |

|

Installation Precision |

Misaligned flanges create uneven pressure, wearing out the joint faster. |

Reduced by 30–50% if misaligned |

Ensure proper alignment during installation, using shims if needed. |

This table outlines key factors influencing the lifespan of flange dismantling joint setups.

Maximizing Dismantling Joint Service Life

- Regular Inspections: Schedule quarterly checks of dismantling joint Look for rust on metal parts, cracks in gaskets, and loose bolts. Early detection of these issues allows for minor repairs, preventing major failures that shorten lifespan. For industrial systems, consider ultrasonic testing every 2–3 years to check for hidden corrosion.

- Proper Lubrication: Apply anti-seize lubricant to dismantling joint bolts twice a year, especially in outdoor or humid environments. This prevents bolts from seizing, making maintenance easier and reducing the risk of bolt breakage during disassembly—broken bolts can render the joint unusable, requiring premature replacement.

- Matching Joint to System Needs: Using a flange dismantling joint rated for higher pressure or temperature than your system requires is unnecessary and costly, but undersizing leads to rapid wear. Consult system specifications to choose the right joint—2025 Hebei honest industrial group’s technical team can help match joints to your needs, ensuring optimal longevity.

Dismantling Joint FAQS

Can a Dismantling Joint Be Repaired, or Must It Be Replaced?

Minor issues like worn gaskets or corroded bolts in a dismantling joint can be repaired. However, if the main body (flange or pipe connection) is cracked or severely corroded, replacement is safer. Repairs can extend lifespan by 5–10 years, but replacement ensures reliability.

How Does Fluid Type Affect Pipe Dismantling Joint Lifespan?

A pipe dismantling joint handling water lasts longer (15–20 years) than one carrying acidic or abrasive fluids. Acids corrode metal, reducing lifespan by 30–40%, while abrasives like slurry wear down gaskets and metal surfaces. Choosing material-matched joints mitigates this.

What’s the Average Lifespan of a Flange Dismantling Joint in a Water Treatment Plant?

In water treatment plants, flange dismantling joint models made of ductile iron with EPDM gaskets typically last 12–15 years. Regular maintenance—like gasket replacement and bolt lubrication—can push this to 18–20 years, making them a cost-effective choice.

Do Dismantling Joints Have a Shelf Life If Not Installed?

Yes, unused dismantling joint components can degrade over time. Gaskets may harden after 5–7 years in storage, and metal parts can rust if not kept dry. Store joints in a cool, dry place, wrapping gaskets in plastic to preserve flexibility.

Where Can I Find Long-Lasting Dismantling Joint Options?

2025 Hebei honest industrial group Co.,Ltd. offers durable dismantling joint products, including pipe dismantling joint and flange dismantling joint models made from high-quality materials. Visit their website to explore their range and get expert advice on choosing joints that maximize service life for your system.

Diele

-

Priming a Pump with a Foot Valve with StrainerNijsAug.23,2025

-

The Importance of a Y Strainer in Pump ProtectionNijsAug.23,2025

-

Stainless Steel Ball Check Valve for High-Purity ApplicationsNijsAug.23,2025

-

Common Applications for Wafer Type Butterfly ValvesNijsAug.23,2025

-

Seat Options for a 12 Inch Knife Gate ValveNijsAug.23,2025