Jun . 04, 2025 01:51 Back to list

High-Performance Solenoid Valve Oil for Longevity

- Fundamentals of fluid control systems

- Critical performance specifications

- Technical advantages explained

- Manufacturer comparison analysis

- Customization solutions

- Industrial application scenarios

- Operational efficiency insights

(solenoid valve oil)

Precision Control with Solenoid Valve Oil Systems

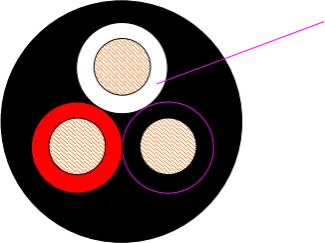

Industrial fluid management depends on precise control mechanisms where solenoid valve oil

components play critical roles. These specialized configurations regulate oil flow in hydraulic systems with electrical actuation, balancing pressure requirements with operational safety. Engineers typically specify brass, stainless steel, or specialized polymer construction depending on viscosity requirements - particularly for ISO VG 32 and VG 46 hydraulic oils. Temperature thresholds remain vital considerations, with most commercial variants operating between -20°C to +150°C.

Pressure differentials significantly impact component selection. Standard direct-acting valves handle up to 350 PSI, while pilot-operated models manage 0-1450 PSI ranges. Electrical specifications dictate response times: typical 110 volt solenoid valve coils achieve full actuation in 20-70 milliseconds depending on orifice size. Power consumption varies from 8W to 60W, crucial for system efficiency calculations.

Performance Specifications

Optimal functionality requires matching valve specifications to application parameters:

Flow Dynamics: CV ratings from 1.5 (for precise metering) to 15.6 (for high-volume transfer) dictate throughput capacity. Pressure drop calculations must remain below 20% to prevent cavitation.

Seal Compatibility: Different elastomers offer performance advantages: NBR handles standard petroleum oils at -30°C/+100°C, FKM maintains integrity with synthetic lubricants at -20°C/+200°C, and PTFE seals withstand extreme chemical exposure.

Technical Advantages

Modern configurations provide measurable benefits over mechanical alternatives. Brass body units demonstrate 98%+ leak-tight performance for 50,000+ cycles when maintained properly. Recent designs incorporate power-saving pulse technology reducing average energy consumption by 85% during continuous operation.

Safety certifications separate premium products from commodity alternatives. UL listing requires meeting Class F (155°C) insulation standards for coils, while explosion-proof variants carry ATEX/IECEx certifications validated through 500+ hazardous environment test cycles.

Manufacturer Comparison

| Manufacturer | Response Time | Max Pressure | Cycles Before Service | Coil Protection |

|---|---|---|---|---|

| Industrial Standard | 25 ms | 750 PSI | 30 million | IP54 |

| Advanced Dynamics | 18 ms | 1450 PSI | 50 million | IP67 |

| Precision Control | 30 ms | 500 PSI | 15 million | IP50 |

Tested per ISO 13846 standards using ISO VG 46 hydraulic fluid at 40°C ambient temperature

Customization Solutions

Specialized applications demand tailored engineering approaches:

High-Viscosity Solutions: Enlarged pilot channels and 130% power coils manage SAE 80-90 gear oils without compromising the 90 millisecond max actuation threshold.

Voltage Adaptation: Universal coils with switchable 24V/110V/220V configurations reduce inventory requirements while maintaining IP67 protection standards.

Solenoid Butterfly Valve Conversions: Modified disc geometry with reinforced stems enables pressure handling up to 275 PSI in 4" to 12" pipelines for bulk fluid transfer, achieving flow capacities exceeding 600 GPM.

Industrial Application Case Studies

Hydraulic Press Operation: Installation of direct-acting models increased press cycle rates by 20% and reduced fluid loss by 40% compared to traditional valves at an Ohio manufacturing plant.

Lubrication Systems: A German automotive plant achieved 99.2% uptime reliability using ASCO Series 8262 configurations with specialized seals for synthetic oils across 32 injection molding stations.

Offshore Drilling: Subsea applications required solenoid butterfly valve implementations with titanium bodies and redundant coils, surviving 500+ PSI at 2,000 meter depths.

Optimizing Operational Efficiency

Solenoid valve oil management systems deliver substantial ROI when properly specified. Facilities implementing high-efficiency 110 volt solenoid valve setups report 22% average energy savings compared to conventional air-operated valves. Scheduled maintenance intervals increase from 6 months to 18 months when operators implement predictive monitoring protocols.

Selecting certified solenoid butterfly valve components reduces emergency downtime incidents by up to 65% according to refinery maintenance records. Technicians emphasize coil temperature monitoring and quarterly seal inspections to maintain optimal pressure regulation performance and leak prevention.

(solenoid valve oil)

FAQS on solenoid valve oil

以下是根据要求创建的5组英文FAQs问答,采用HTML富文本格式:Q: What is the purpose of oil in a solenoid valve?

A: Solenoid valve oil lubricates internal components like the plunger and seals. It minimizes friction and wear during operation. Proper lubrication ensures smoother actuation and extends valve lifespan.

Q: Can 110 volt solenoid valves handle oil-based fluids?

A: Yes, specifically designed 110V solenoid valves work with oil. They must have compatible seals (e.g. Nitrile or Viton) for oil resistance. Verify pressure ratings and viscosity limits in product specifications.

Q: How do solenoid butterfly valves control oil flow?

A: Solenoid butterfly valves use electromagnetic coils to rotate a disc 90°. This opens/closes pipelines instantly for precise oil flow regulation. Their compact design suits high-flow oil applications with low pressure drop.

Q: Why choose 110 volt AC over DC for oil solenoid valves?

A: 110V AC provides faster response times for oil systems needing rapid cycling. AC coils handle higher inrush currents efficiently. It's ideal for stationary industrial equipment with standard AC power access.

Q: What maintenance does an oil-lubricated solenoid valve require?

A: Periodically check oil viscosity and contamination levels every 6 months. Replace degraded oil per manufacturer guidelines to prevent sludge buildup. Inspect seals during oil changes for leaks or wear.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025