elo . 28, 2024 11:04 Back to list

Wafer Style Butterfly Valve - Precision and Performance

The Wafer Style Butterfly Valve An Essential Component for Fluid Control

The wafer style butterfly valve is an increasingly popular choice in various industries for controlling the flow of liquids and gases. This type of valve is characterized by its simple design, compact structure, and effectiveness in applications requiring tight shut-off capabilities. With its innovative functionality, the wafer style butterfly valve plays a crucial role in enhancing operational efficiency across different systems.

One of the primary advantages of the wafer style butterfly valve is its space-saving design. Unlike traditional valves that may be bulky and heavy, wafer butterfly valves are lightweight and require minimal installation space. This makes them particularly advantageous in environments where space is at a premium, such as in chemical processing plants, water treatment facilities, and HVAC systems. Their compact design not only simplifies installation but also reduces the overall weight of piping systems, which can be crucial in specific engineering applications.

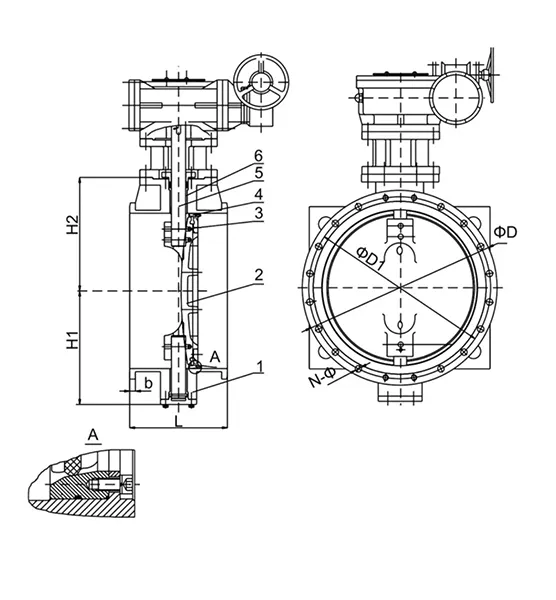

The operation of a wafer style butterfly valve involves a disc, or butterfly, that rotates within the pipe to either open or close the flow path. This mechanism enables quick and efficient throttling of fluid flows, providing operators with excellent control over system operations. The ease of operation is complemented by the valve's ability to achieve a tight seal, which minimizes leakage and ensures the integrity of the system. This makes wafer style butterfly valves suitable for handling various fluids, including slurries, gases, and aggressive chemicals.

wafer style butterfly valve

Furthermore, the materials used in the construction of wafer style butterfly valves are often resistant to corrosion and wear, ensuring longevity and reliability in challenging environments. Common materials include stainless steel, ductile iron, and plastics, allowing these valves to be tailored to suit specific applications and requirements.

In addition to their practical advantages, wafer style butterfly valves are also cost-effective. Their simple design reduces manufacturing costs, and their lightweight nature can lead to savings on installation and support structures.

In conclusion, wafer style butterfly valves are an essential component in modern fluid control systems. Their compact design, efficiency in operation, and reliability in service make them a preferred choice for engineers and operators alike. As industries continue to seek solutions that enhance performance and reduce operational costs, the wafer style butterfly valve will undoubtedly remain a key player in the realm of valve technology. With ongoing advancements and innovations in this field, the future of wafer style butterfly valves looks bright, promising even greater versatility and efficiency in fluid control applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025