nov. . 24, 2024 09:06 Back to list

pn16 check valve

Understanding PN16 Check Valves An Overview

Check valves play a pivotal role in various industrial applications by ensuring the unidirectional flow of fluids. Among the array of check valves available in the market, the PN16 check valve stands out due to its specific design and operational features suited for certain pressure and flow conditions. In this article, we will delve into the mechanics, applications, advantages, and maintenance practices pertaining to PN16 check valves.

What is a PN16 Check Valve?

The designation PN16 refers to the nominal pressure rating of the valve, where PN stands for Pressure Nominal and the number indicates the maximum pressure in bars that the valve can handle. A PN16 check valve can sustain pressures up to 16 bar, making it ideal for a multitude of applications that require reliable performance under substantial pressure levels.

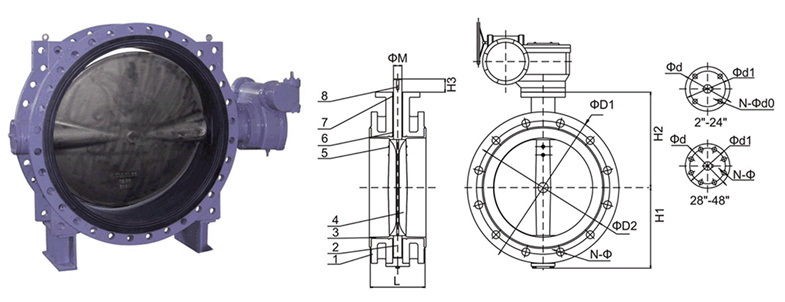

A typical PN16 check valve consists of a body, a disc (or flap), and a seat. The disc is the crucial component that opens and closes the flow path. When fluid flows in the designated direction, the disc lifts, allowing passage. Conversely, if the flow attempts to reverse, the disc closes, preventing backflow. This mechanism is vital for preventing damage to pumping equipment and other process components.

Types of PN16 Check Valves

There are various designs of PN16 check valves, including

1. Swing Check Valves These valves utilize a hinged disc that swings open with forward flow and swings closed under reverse flow. They are commonly used in low-pressure applications.

2. Lift Check Valves This design features a piston-like disc that rises and falls in response to pressure changes. Lift check valves are often preferred in high-pressure scenarios.

3. Dual Plate Check Valves Characterized by two plates that open and close simultaneously, providing a compact design suitable for high flow applications.

Each type has its unique advantages and is selected based on specific process requirements.

Applications of PN16 Check Valves

PN16 check valves are widely used in both industrial and domestic applications. Common sectors include

- Water Treatment Plants They help manage the flow and prevent backflow in water supply systems. - Pumping Stations Prevents reverse flow that could damage pumps and associated equipment. - Chemical Processing Protects delicate machinery by ensuring that fluids do not flow back into systems where they can cause contamination or damage. - Heating Systems Ensures that hot water systems function correctly by preventing reverse flow, thus maintaining efficiency.

pn16 check valve

Advantages of PN16 Check Valves

1

. Enhanced Safety By preventing backflow, check valves help to avert potential hazards in fluid handling systems, thus ensuring operational safety.2. Operational Efficiency They contribute to the optimal performance of pumping systems by allowing unidirectional flow, reducing the risk of system failures.

3. Durability Made from robust materials, PN16 check valves can withstand high pressures and aggressive chemicals, ensuring longevity and reliability.

4. Cost-Effectiveness Investing in quality check valves can reduce maintenance costs and downtime, contributing to overall cost savings within a facility.

Maintenance of PN16 Check Valves

To ensure the longevity and efficiency of PN16 check valves, proper maintenance is crucial. Here are some maintenance practices to consider

- Regular Inspections Conduct periodic checks to ensure that the valve operates smoothly and is free from debris that could impede functionality.

- Cleaning Clean the valve components if fluid buildup is observed. This helps maintain the smooth operation of the disc.

- Check Seals and Gaskets Worn-out seals can lead to leaks. Regularly check and replace seals and gaskets as needed to ensure a tight seal.

- Functional Testing Periodically test the valve's operation to verify its responsiveness to changes in flow direction.

Conclusion

The PN16 check valve is an indispensable component in fluid handling systems across various industries. Its design, functionality, and ability to handle significant pressure make it a reliable choice for engineers and facility managers alike. By understanding the features, applications, and maintenance requirements of these check valves, businesses can ensure efficient operations and extend the lifespan of their equipment. When choosing a check valve, consider integrating PN16 models to maximize performance and enhance safety in your fluid systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025