nov. . 22, 2024 14:36 Back to list

industrial globe valve

The Industrial Globe Valve An Essential Component in Fluid Control

The industrial globe valve is a vital component in various industries, including oil and gas, water treatment, and chemical processing. Renowned for its efficiency in regulating flow, this valve design is characterized by its spherical body and an internal baffle that directs the flow of fluids. While it may seem simple, understanding its features and applications reveals why it is indispensable in industrial settings.

Design and Functionality

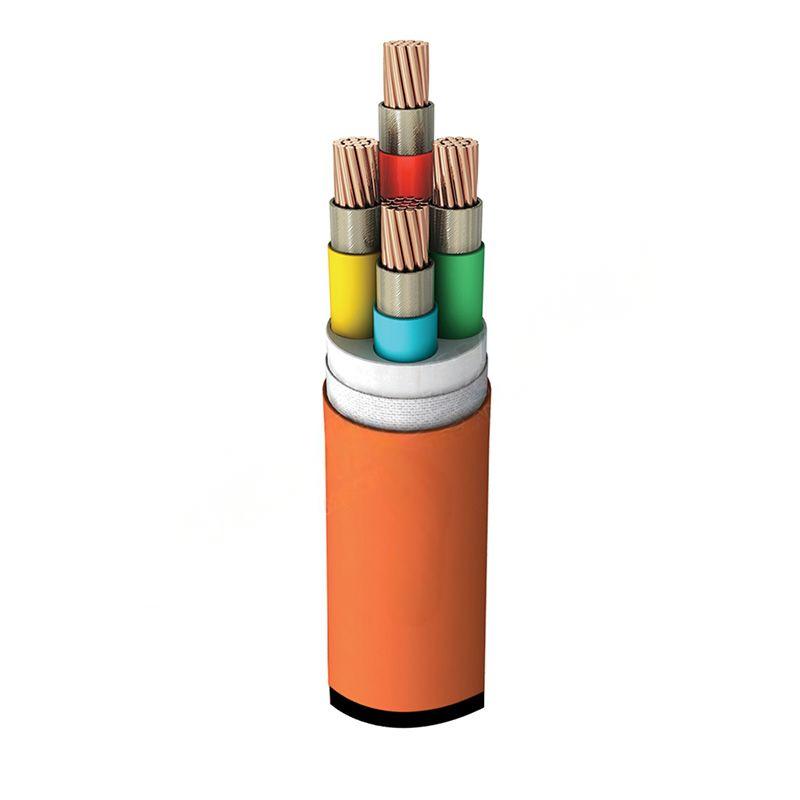

The globe valve's design plays a significant role in its functionality. The valve consists of a spherical body with an inlet and outlet, connected by a passageway that allows for fluid movement. Unlike other valve types that open and close entirely, globe valves are primarily used for throttling services – that is, controlling the flow rate rather than simply on/off functions. The disk or plug moves vertically in the valve body, which provides precise control over the flow of the medium.

Another advantage of the globe valve is its ability to handle high-pressure applications and its robust nature, making it suitable for various fluid types, including gases and corrosive substances. The seat and disk can be designed with materials that improve durability and reduce wear, such as stainless steel or special alloys, enhancing their longevity and reducing maintenance needs.

Applications in Industry

Globe valves are widely used in many industries due to their excellent flow control capabilities. In the oil and gas sector, they manage the flow of crude oil and natural gas at various stages, ensuring that the distribution process remains smooth and efficient. Similarly, in water treatment plants, globe valves control the flow of water through filtration and purification processes, maintaining optimal treatment levels.

industrial globe valve

In the chemical industry, these valves are essential for controlling the flow of corrosive substances and ensuring safe operation. Their design minimizes the risk of leaks, which is critical when dealing with hazardous chemicals. Additionally, globe valves are commonly found in power plants, where they regulate steam flow for turbines, ensuring optimal performance and efficiency.

Advantages Over Other Valve Types

One of the key advantages of globe valves over other valve types, such as gate or ball valves, is their precise control over fluid flow. While gate valves are often favored for on/off services due to their low resistance when fully open, they can struggle with flow regulation. Similarly, ball valves offer quick operation but lack the precision needed for throttling applications. Globe valves bridge this gap by providing a reliable solution for industries that require fine-tuned flow control.

Moreover, globe valves provide better pressure drop control compared to other valve types. This characteristic is particularly critical in processes that require maintaining specific pressure levels within pipelines.

Conclusion

In conclusion, the industrial globe valve is a crucial element in the realm of fluid control. Its unique design allows for precise throttling and reliable performance across various industries, from oil and gas to chemical processing. By maintaining optimal flow rates and minimizing the risk of leaks, globe valves play an integral role in ensuring safety and efficiency in industrial operations. As industries continue to evolve, the significance of robust and efficient components like the globe valve will only grow, making it a staple in future fluid management systems. Whether dealing with water, oil, or hazardous chemicals, the globe valve remains a trusted choice for engineers and technicians alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025