Nov . 09, 2024 05:54 Back to list

MSS Metal Seating for Enhanced Performance in Gate Valve Design and Functionality

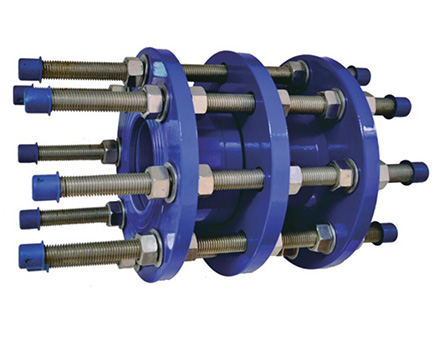

Understanding MSS Metal Seat Gate Valves

Metal seat gate valves are crucial components in various industrial applications, known for their durability and performance in challenging environments. The MSS (Manufacturers Standardization Society) specifications provide guidelines that ensure these valves maintain high standards for design, manufacturing, and testing. This article delves into the characteristics, applications, and benefits of MSS metal seat gate valves, helping you understand their importance in fluid control systems.

Characteristics of MSS Metal Seat Gate Valves

MSS metal seat gate valves are typically constructed with a metal-to-metal seating surface, offering superior sealing capabilities compared to their softer seated counterparts. This design makes them particularly suitable for high-pressure and high-temperature applications. The metal seat's durability reduces the likelihood of wear and damage over time, leading to a longer service life.

One of the notable features of metal seat gate valves is their ability to handle abrasive media. Industries such as mining and chemical processing often deal with materials that can cause erosive wear on standard valves. The robust construction of metal seat gate valves allows them to withstand such conditions without compromising performance.

MSS standards outline various design parameters, including the dimensions, materials, and testing methods for these valves. Ensuring compliance with these standards guarantees that the valves not only perform effectively but also meet safety and reliability benchmarks.

Applications of MSS Metal Seat Gate Valves

MSS metal seat gate valves are widely used across multiple industries, including oil and gas, water distribution, chemical manufacturing, and power generation. In the oil and gas sector, these valves play a pivotal role in controlling the flow of crude oil, natural gas, and other substances through pipelines. Their ability to handle high pressures and temperatures makes them ideal for upstream and downstream applications.

In water distribution systems, metal seat gate valves are essential for managing the flow of potable water and sewage

. Their reliability ensures minimal leakage and allows for effective isolation, which is critical for maintenance and emergency response situations.mss metal seat gate valve

In chemical manufacturing, where corrosive materials may be present, the durable construction of metal seat gate valves provides an added layer of safety for personnel and the environment. By ensuring a tight seal, these valves help prevent leaks that could result in hazardous situations.

Power generation facilities also utilize MSS metal seat gate valves, particularly in steam applications and cooling water systems. Their performance in fluctuating temperatures and pressures makes them an indispensable part of the infrastructure.

Benefits of MSS Metal Seat Gate Valves

The primary benefit of using MSS metal seat gate valves is their outstanding durability. The metal seating surfaces can endure extreme conditions, resulting in reduced maintenance costs and extended service intervals. This reliability translates to enhanced operational efficiency and lower total cost of ownership over time.

Another advantage is their exceptional sealing capabilities. The metal-to-metal seating arrangement minimizes the chances of leakage, which is crucial in applications where fluid integrity is paramount. In industries where even a small leak can lead to significant environmental or economic consequences, the performance of metal seat gate valves can be a game-changer.

Furthermore, MSS metal seat gate valves are versatile and can be customized to meet specific operational requirements. They are available in various sizes, materials, and pressure ratings, allowing for widespread application across different sectors. Whether you need a valve for a high-pressure pipeline or a low-temperature chemical process, there is likely an MSS-compliant metal seat gate valve suitable for your needs.

Conclusion

In summary, MSS metal seat gate valves are integral to the effective management of fluid systems in various industries. Their robust design, adherence to standardized specifications, and excellent sealing capabilities make them a favored choice for engineers and operators alike. Understanding the characteristics and applications of these valves is essential for anyone involved in industrial processes, ensuring that they can make informed decisions that promote safety and efficiency. As industries continue to evolve, the demand for reliable and high-performance valve solutions like MSS metal seat gate valves remains paramount.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025