Δεκ . 28, 2024 10:40 Back to list

flanged swing check valve

Understanding Flanged Swing Check Valves

Flanged swing check valves are critical components in various piping systems, widely utilized for their reliability and efficiency in preventing backflow. These specialized valves are engineered to allow fluid flow in one direction while automatically closing when the flow reverses, thus safeguarding the system from potential damage caused by backpressure.

Construction and Features

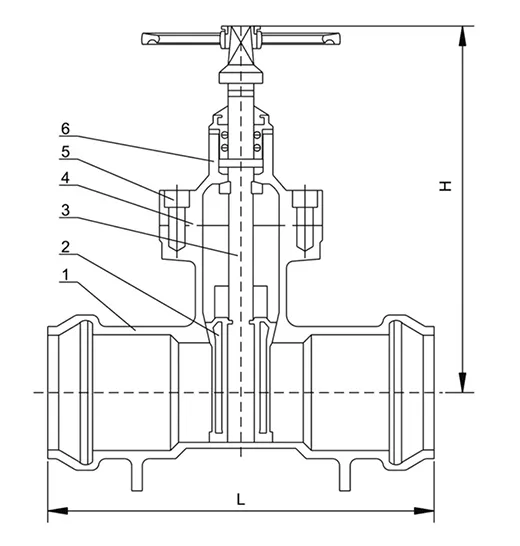

A flanged swing check valve typically consists of a disc, body, hinge, and flange connections. The body is designed to resist the pressures and temperatures prevalent in industrial applications, often made from durable materials such as cast iron, stainless steel, or bronze. The disc, which swings on a hinge, plays a pivotal role in the valve’s operation. During normal flow, the disc remains open, allowing fluid to pass through. However, if the flow direction attempts to reverse, the disc swings back onto its seat, effectively sealing the valve and preventing backflow.

The flanged ends of the valve make it easy to install within the piping system, providing a secure connection that can withstand vibration and dynamic forces. This design not only simplifies maintenance but also ensures leak-free operation.

Advantages of Flanged Swing Check Valves

1. Efficiency in Flow Control One of the primary benefits of flanged swing check valves is their minimal pressure drop across the valve. The streamlined design allows fluids to pass through with little resistance, optimizing energy efficiency within the system.

2. Automatic Operation Unlike manual valves, swing check valves operate automatically. When the flow stops or reverses, the disc closes, negating the need for manual intervention and reducing the risk of human error.

3. Robustness and Longevity Constructed from strong materials and designed to handle high pressures and temperatures, flanged swing check valves are reliable for long-term use, making them a cost-effective solution in the long run.

4. Versatility These valves are suitable for a wide range of applications, including water, oil, gas, and steam systems. Their design can accommodate various flow rates and media types, enhancing their utility across different industries.

flanged swing check valve

5. Simple Maintenance The design of flanged swing check valves allows for easy disassembly and reassembly, making them user-friendly during maintenance. Regular inspection and cleaning can be performed without extensive downtime.

Applications

Flanged swing check valves are widely used in various sectors, including

- Water Treatment Plants To prevent backflow and ensure the proper functioning of the treatment process. - Power Generation In steam and water systems, where efficient flow control is vital for operational integrity. - Oil and Gas Industry To safeguard pipelines from backpressure caused by fluctuations in fluid dynamics. - HVAC Systems Ensuring that chilled or heated water flows in the desired direction without the risk of contamination.

Installation and Considerations

Proper installation of flanged swing check valves is essential to ensure optimal performance. They should be installed with the flow direction indicated on the valve body, while the flanges should be aligned properly to prevent undue stress during operation. It is also crucial to select the appropriate valve size to match the pipeline diameter and flow requirements.

In addition, considerations for temperature, pressure ratings, and the type of fluid being handled must be taken into account. Consulting with the manufacturer’s specifications and guidelines can help in selecting the right valve for specific applications.

Conclusion

Flanged swing check valves are indispensable in modern engineering, providing an effective solution for controlling fluid flow and preventing backflow in various systems. Their robust design, automatic operation, and efficiency make them a favored choice among engineers and system designers. With proper maintenance and installation, these valves can significantly enhance the safety and reliability of fluid conveyance systems, ensuring continuous and trouble-free operation in diverse industrial applications. As industries continue to evolve, the demand for reliable and efficient components like flanged swing check valves is expected to grow, underscoring their importance in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025