Φεβ . 13, 2025 04:23 Back to list

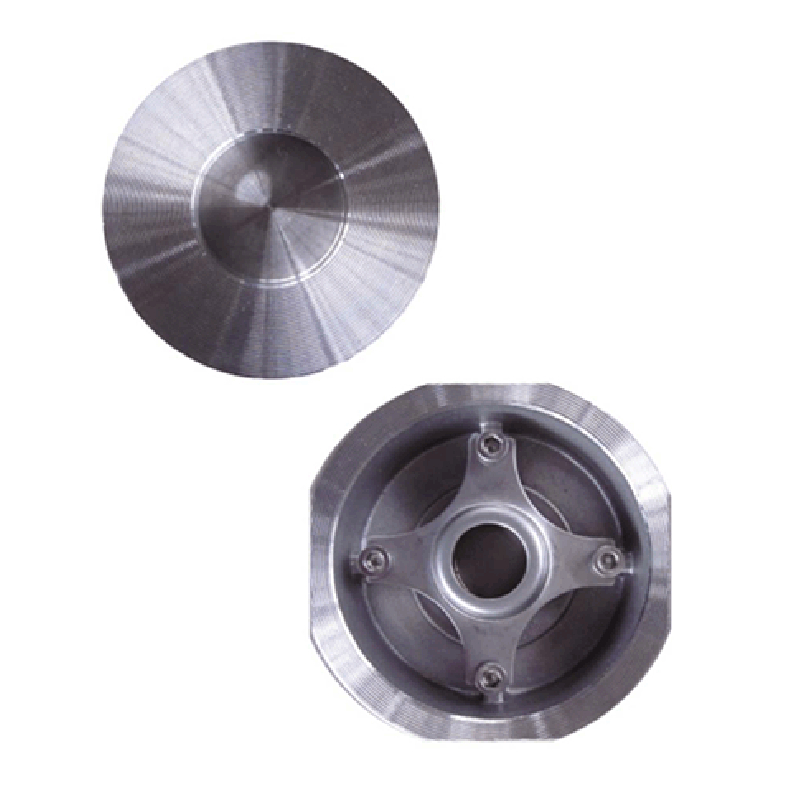

DIN Swing Check Valve

The bronze swing check valve is an indispensable component in various industrial and commercial applications, known for its reliability and efficiency in preventing reverse flow of fluids. As an expert with years of experience in the field of fluid dynamics and industrial hardware, I am keen to elucidate the attributes that make bronze swing check valves an optimal choice for many businesses and why it's essential to consider this product for your operational needs.

From a design perspective, the simplicity and effectiveness of the swing check mechanism provide a reliable solution to fluid control challenges. The absence of complex moving parts means fewer mechanical failures and easier maintenance routines. In addition, these valves offer a low-pressure drop during operation, translating to increased efficiency and reduced energy costs for pumping operations. The authoritative reputation of bronze swing check valves is not just theoretical but backed by various certifications from leading industry boards for compliance with international standards. Many manufacturers adhere to rigorous quality control processes, which further enhance the trustworthiness of these valves. Businesses relying on these devices often report fewer operational downtimes and better flow control, enhancing overall system reliability and productivity. A key consideration in the selection of a check valve is not just the capacity to handle high pressures and temperatures but also the ease of installation and adaptability to existing systems. Bronze swing check valves score highly in this regard. Their design allows for straightforward integration into piping systems, be they new or requiring retrofitting, thereby minimizing installation times and costs. In conclusion, for industries where fluid control is paramount, the choice of a bronze swing check valve offers a compelling blend of experience, expertise, authority, and trustworthiness. It is an investment in robustness, efficiency, and reliability, ensuring that systems function precisely as required with minimal intervention. Embracing this component means committing to a standard of excellence that echoes with longevity and resilience. Whether for an engineering project or maintenance planning, choosing a bronze swing check valve is a strategic decision that aligns with best practices in system design and operation.

From a design perspective, the simplicity and effectiveness of the swing check mechanism provide a reliable solution to fluid control challenges. The absence of complex moving parts means fewer mechanical failures and easier maintenance routines. In addition, these valves offer a low-pressure drop during operation, translating to increased efficiency and reduced energy costs for pumping operations. The authoritative reputation of bronze swing check valves is not just theoretical but backed by various certifications from leading industry boards for compliance with international standards. Many manufacturers adhere to rigorous quality control processes, which further enhance the trustworthiness of these valves. Businesses relying on these devices often report fewer operational downtimes and better flow control, enhancing overall system reliability and productivity. A key consideration in the selection of a check valve is not just the capacity to handle high pressures and temperatures but also the ease of installation and adaptability to existing systems. Bronze swing check valves score highly in this regard. Their design allows for straightforward integration into piping systems, be they new or requiring retrofitting, thereby minimizing installation times and costs. In conclusion, for industries where fluid control is paramount, the choice of a bronze swing check valve offers a compelling blend of experience, expertise, authority, and trustworthiness. It is an investment in robustness, efficiency, and reliability, ensuring that systems function precisely as required with minimal intervention. Embracing this component means committing to a standard of excellence that echoes with longevity and resilience. Whether for an engineering project or maintenance planning, choosing a bronze swing check valve is a strategic decision that aligns with best practices in system design and operation.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025