Nov . 09, 2024 04:52 Back to list

Exploring the Benefits of Triple Offset Butterfly Valves in Modern Engineering Applications

Understanding the Triple Offset Butterfly Valve

The triple offset butterfly valve is an advanced type of valve widely utilized in various industries such as oil and gas, water treatment, and power generation. Known for its unique design and enhanced sealing capabilities, this valve has become an essential component in managing fluid flow effectively and efficiently.

Design Features

The term triple offset refers to the three distinct offsets in the valve's design. The first offset is the tilt of the valve disc, which is positioned at an angle to the valve seat. This tilt allows the disc to open and close smoothly with minimal friction. The second offset is the centerline of the valve shaft, which is not aligned with the valve seat, and the third offset is the geometry of the seat itself. These three offsets work together to create a more efficient sealing mechanism, reducing wear and minimizing the risk of leaks.

The triple offset butterfly valve typically features a metal-to-metal seating arrangement, which ensures a secure sealing even in high-pressure applications. This design allows the valve to handle various fluid types, including corrosive and abrasive materials, making it highly versatile.

Benefits of Triple Offset Butterfly Valves

One of the most notable advantages of triple offset butterfly valves is their superior sealing capability. Unlike traditional butterfly valves, which may rely on soft materials for sealing, triple offset valves use a rigid seating surface that ensures a tight shutoff. This capability is particularly important in applications where leakage can lead to safety hazards or environmental issues.

Additionally, the triple offset design results in a lower torque requirement for operation, which translates to reduced actuator sizes and lower energy consumption. This can lead to significant cost savings during installation and operation. The compact structure of these valves also means that they can be integrated into tight spaces, providing flexibility in design and installation.

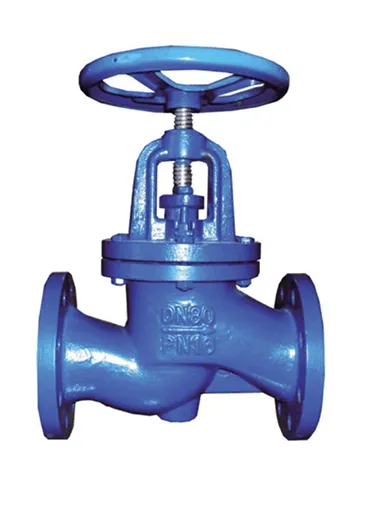

triple offset butterfly valve

Another key benefit is the durability of the valve. The metal-to-metal seating means that there is less wear over time, extending the lifespan of the valve and reducing the need for frequent replacements. This longevity makes the triple offset butterfly valve an economically favorable option for industries that experience demanding conditions.

Applications

The triple offset butterfly valve is used in a variety of applications due to its robust construction and reliability. In the oil and gas industry, it is employed in upstream, midstream, and downstream processes, handling everything from crude oil to natural gas. Its ability to withstand high temperatures and pressures makes it ideal for these critical applications.

In water treatment facilities, the valve is used to manage the flow of water efficiently, ensuring that the treatment processes run smoothly. Its resilience against corrosion and scaling allows for effective operation in harsh environments typical of such facilities.

Power generation facilities also benefit from the use of triple offset butterfly valves, especially in steam, gas, and hydronic systems. Their ability to handle high flow rates and pressures makes them an optimal choice for controlling the flow of energy resources.

Conclusion

The triple offset butterfly valve stands out as a reliable and efficient solution for various industrial applications. Its innovative design and superior sealing capabilities provide significant advantages over traditional valves. With a focus on durability, lower torque requirements, and versatility, these valves are ideal for managing flow control in critical systems. As industries continue to evolve and demand more effective solutions, the triple offset butterfly valve will undoubtedly play a crucial role in ensuring safe and efficient operations across multiple sectors.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025