dec . 10, 2024 07:47 Back to list

Flange Adaptors and Dismantling Joints for Efficient Pipeline Connections and Maintenance Solutions

Understanding Flange Adaptors and Dismantling Joints Key Components in Pipeline Systems

In the realm of pipeline systems, ensuring the seamless connection of various components while maintaining flexibility for maintenance is crucial. Two essential tools that facilitate these objectives are flange adaptors and dismantling joints. Both play significant roles in the installation and maintenance of pipelines in various industries, including water, gas, and oil sectors.

Flange Adaptors A Gateway to Compatibility

Flange adaptors are devices used to connect pipes with different standards or materials while allowing for a strong and secure bond. Typically, these adaptors feature a flange on one end, which is bolted to a compatible flange on another pipe or fitting. The other end is designed to fit the pipe type in question, providing vital versatility in pipeline installations.

The construction of flange adaptors can vary greatly, accommodating materials such as ductile iron, PVC, stainless steel, and others. This diversity ensures that they can be used in a variety of applications, ranging from domestic plumbing to industrial systems. Moreover, the design often includes features that enhance performance, such as gaskets for leak prevention and corrosion resistance to extend their lifespan.

The importance of flange adaptors lies in their ability to facilitate connections that might otherwise be impossible or impractical. For instance, when renovating older infrastructure, it may be necessary to connect new piping materials with legacy systems. Flange adaptors bridge this gap, ensuring that operational efficiencies are not compromised by incompatible materials.

Dismantling Joints The Maintenance Solution

Dismantling joints are another critical component in pipeline systems, designed specifically to simplify the maintenance and replacement of piping. They provide a flexible connection point, enabling sections of the pipeline to be easily removed and replaced without the need for extensive disassembly of adjoining components. This is particularly beneficial in tight spaces or complex pipeline layouts where access may be limited.

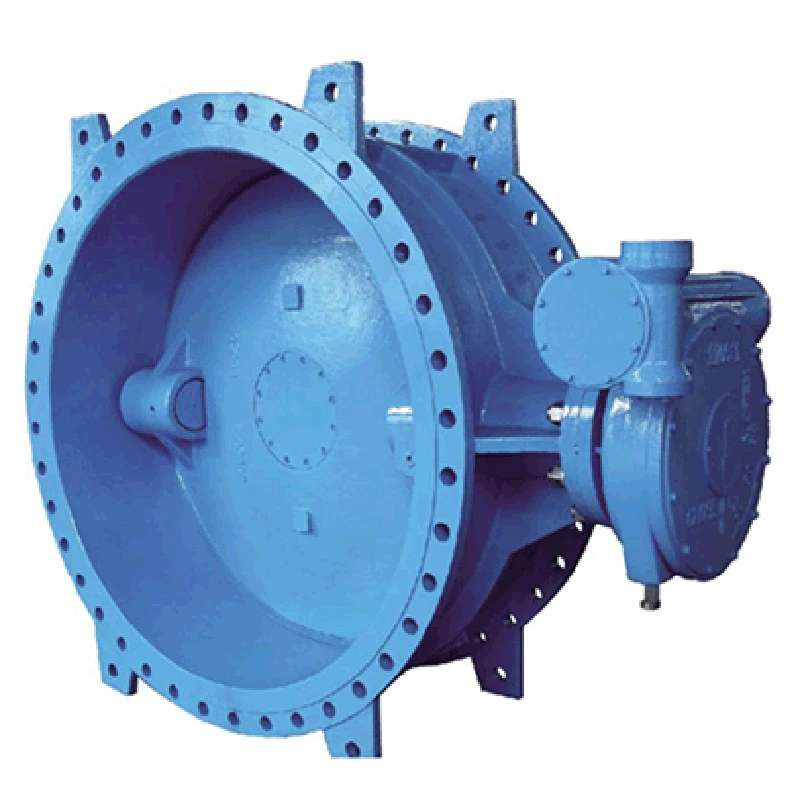

flange adaptor and dismantling joint

The function of a dismantling joint is to allow for axial movement, which provides the required clearance for pipe removal. Typically, these joints are constructed with sliding mechanisms and are designed to accommodate different pipe diameters. This adaptability makes them invaluable for maintenance crews, who can perform repairs or inspections more efficiently and with less downtime.

Dismantling joints also incorporate advanced sealing technologies, ensuring that connections remain leak-free during operation. This is crucial in maintaining the integrity of pipeline systems, especially in industries where environmental regulations are stringent. By facilitating quick and easy access to pipelines, dismantling joints contribute significantly to overall operational efficiency.

Integration of Flange Adaptors and Dismantling Joints

When incorporated into pipeline systems, flange adaptors and dismantling joints work synergistically to enhance functionality. Flange adaptors ensure that disparate piping systems can connect effortlessly, while dismantling joints provide the necessary access for inspection and maintenance. Together, they create a robust and flexible pipeline architecture that can adapt to changing operational needs.

The combination of these two components is particularly beneficial in large-scale projects where uptime is critical. Facilities such as water treatment plants, gas distribution networks, and industrial manufacturing operations benefit from this integrated approach, minimizing downtime and reducing maintenance costs.

Conclusion

In summary, flange adaptors and dismantling joints are essential components in the design and maintenance of pipeline systems. Their ability to provide secure connections while facilitating maintenance underscores their importance across various industries. As technology advances, these components will continue to evolve, driving improvements in pipeline efficiency, safety, and sustainability. Understanding their function and application can empower professionals to make informed decisions that enhance service delivery and operational performance in pipeline infrastructures.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025