jan . 06, 2025 18:57 Back to list

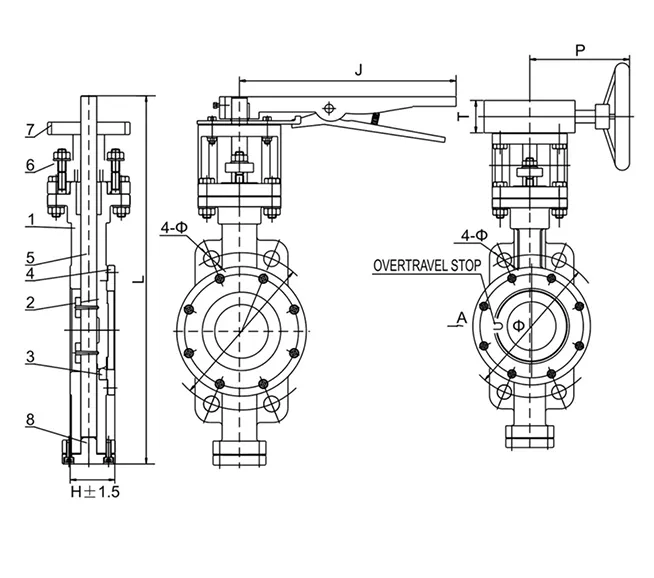

flange type butterfly valve

Butterfly valves, widely regarded as a key component in fluid management systems, offer unique advantages due to their design and function. As someone with extensive experience in industrial valve solutions, I am confident in the benefits butterfly valves deliver across various applications.

At the heart of butterfly valves lies a disc that rotates around a central axis, opening and closing to regulate or isolate fluid flow. This simple yet efficient mechanism allows for quick operation, typically requiring a 90-degree turn to move from fully open to fully closed. This quick action is particularly advantageous in emergency situations where immediate flow control is essential.

A primary expertise area is understanding the diverse material options available for constructing butterfly valves. Metals like stainless steel and cast iron offer durability and strength for industrial applications, while options such as PVC or PTFE are valued for their chemical resistance in corrosive environments. Choosing the right material ensures longevity and optimal performance, reducing maintenance costs and improving system efficiency.

From an authoritative perspective, butterfly valves are preferred in industries ranging from water treatment to petrochemicals due to their compact size and lightweight structure compared to gate or ball valves. These qualities not only reduce material costs but also simplify installation. Additionally, butterfly valves provide excellent throttling capabilities with low pressure drops, making them highly efficient in managing flow rates and reducing energy consumption.

butterfly valve

Trustworthiness in valve performance is paramount. Modern advancements have introduced high-performance butterfly valves, designed to withstand severe conditions, such as high-pressure applications and extreme temperatures, further expanding their reliability. These enhancements are supported by rigorous testing standards, ensuring valves meet industry certifications before they are deployed in critical environments.

In real-world applications, butterfly valves have consistently demonstrated their versatility. In water distribution networks, they prove critical for isolating sections during maintenance, minimizing service disruptions. In chemical processing, their resistance to detrimental substances ensures continuity and safety in operations. By maintaining optimal fluid control, they contribute directly to the integrity and efficiency of entire systems.

In conclusion, the comprehensive benefits of butterfly valves stem from their innovative design and material versatility. Their unparalleled efficiency, coupled with reliable performance across diverse sectors, makes them a crucial component for modern fluid management needs. For those seeking expert advice on integrating butterfly valves into their systems, consultation with industry professionals can provide invaluable insights, ensuring that valve selection aligns with specific operational demands and future growth.

Share