Chw . 05, 2025 04:16 Back to list

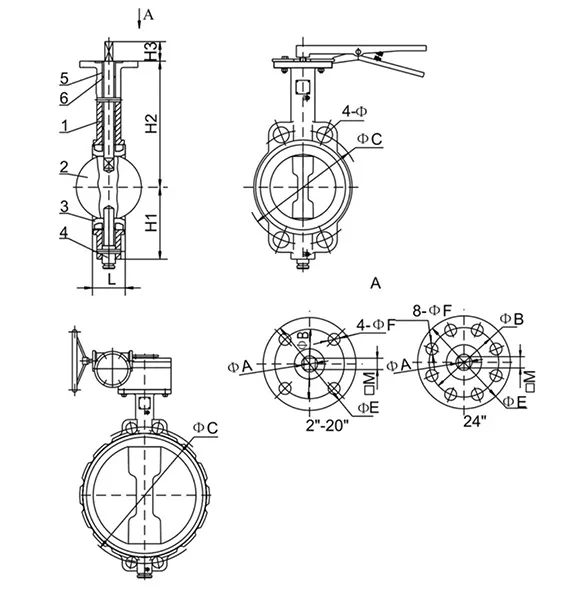

wafer type gate valve

Gate valve actuators serve as pivotal components in various industrial settings where the control of fluid flow is crucial. Their application spans across industries like water treatment, oil and gas, and manufacturing, making them indispensable for efficient and effective operations. Selecting the right gate valve actuator necessitates a combination of engineering precision, technical insight, and a profound understanding of operational environments.

Trustworthiness in gate valve actuators is often built through rigorous field testing and proven performance records. Testimonials from industry leaders and field operators can significantly underpin the credibility of a specific actuator brand or model. A documented instance where a particular actuator withstood extreme temperature fluctuations while maintaining optimal performance showcases its reliability and fortifies user trust. In terms of product features, modern gate valve actuators are praised for their modular design which facilitates easy installation and maintenance. This aspect is particularly beneficial for industries facing frequent operational changes, enabling quick adaptability without significant downtime. Additionally, energy efficiency is a critical feature, with several manufacturers focusing on minimizing power consumption while maximizing output, aligning with global sustainability goals. In closing, the role of gate valve actuators in industrial applications cannot be overstated. As technology continues to evolve, these devices are poised to offer even more sophisticated solutions to fluid control challenges. Organizations investing in high-quality gate valve actuators are likely to witness not only enhanced efficiency and safety standards but also strategic advantages in terms of cost savings and operational agility. For any enterprise aiming to maintain a competitive edge, a focus on the latest advancements in gate valve actuators is not just an option, but a necessity.

Trustworthiness in gate valve actuators is often built through rigorous field testing and proven performance records. Testimonials from industry leaders and field operators can significantly underpin the credibility of a specific actuator brand or model. A documented instance where a particular actuator withstood extreme temperature fluctuations while maintaining optimal performance showcases its reliability and fortifies user trust. In terms of product features, modern gate valve actuators are praised for their modular design which facilitates easy installation and maintenance. This aspect is particularly beneficial for industries facing frequent operational changes, enabling quick adaptability without significant downtime. Additionally, energy efficiency is a critical feature, with several manufacturers focusing on minimizing power consumption while maximizing output, aligning with global sustainability goals. In closing, the role of gate valve actuators in industrial applications cannot be overstated. As technology continues to evolve, these devices are poised to offer even more sophisticated solutions to fluid control challenges. Organizations investing in high-quality gate valve actuators are likely to witness not only enhanced efficiency and safety standards but also strategic advantages in terms of cost savings and operational agility. For any enterprise aiming to maintain a competitive edge, a focus on the latest advancements in gate valve actuators is not just an option, but a necessity.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025