Úno . 12, 2025 18:39 Back to list

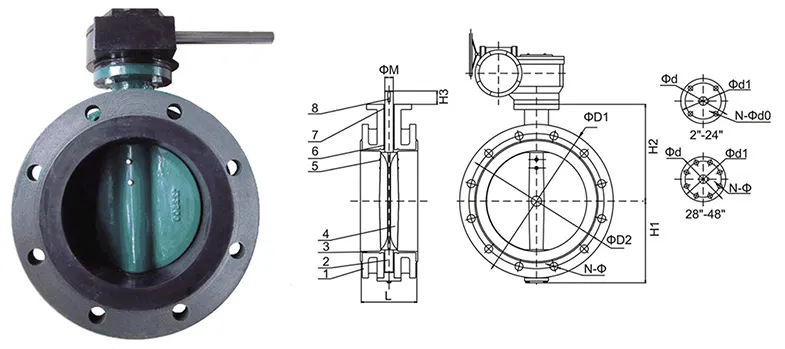

vulcanized seat flange butterfly valve

Navigating the complexities of industrial valves can seem daunting, yet choosing the right type for specific applications is crucial for maintaining operational efficiency and safety. The vulcanized seat flange butterfly valve stands out as a pivotal component in fluid control systems across diverse industries, from chemical processing to water treatment facilities.

Moreover, the design and material of the valve's disc play a critical role. Typically made of stainless steel or ductile iron, the disc must offer the right balance between structural strength and corrosion resistance, depending on the service conditions. Here again, engaging with specialized valve manufacturers and suppliers can provide insights into the optimal choice, ensuring the valve's longevity and reliability, particularly in demanding environments. Authoritativeness in the selection and application of vulcanized seat flange butterfly valves is reinforced by adhering to industry standards and certifications. Well-established standards such as ISO 9001, API, ASME, and ANSI provide comprehensive guidelines on quality and safety. Therefore, selecting valves certified by reputable organizations ensures adherence to the highest industry benchmarks, a critical consideration for projects involving stringent regulatory compliance. Trustworthiness, often gained through verifiable testimonials and case studies, is critical while making purchasing decisions. Leading manufacturers and suppliers not only provide extensive documentation on their valve's performance but also allow potential buyers to access case studies detailing successful implementations. This transparency builds confidence, ensuring that clients can make informed decisions backed by real-world performance data. In summary, the vulcanized seat flange butterfly valve represents a significant advancement in valve technology tailored to demanding industrial applications. Its strength lies in its ability to combine flexibility in operations with seal integrity, backed by strategic material choice and compliance with international standards. By engaging with experts and leveraging industry insights, businesses can enhance their liquid handling systems' efficiency, ensuring operational safety and longevity. As industries continue to evolve, staying informed on technological advancements, material science innovations, and regulatory changes will be key to leveraging the full potential of these indispensable components.

Moreover, the design and material of the valve's disc play a critical role. Typically made of stainless steel or ductile iron, the disc must offer the right balance between structural strength and corrosion resistance, depending on the service conditions. Here again, engaging with specialized valve manufacturers and suppliers can provide insights into the optimal choice, ensuring the valve's longevity and reliability, particularly in demanding environments. Authoritativeness in the selection and application of vulcanized seat flange butterfly valves is reinforced by adhering to industry standards and certifications. Well-established standards such as ISO 9001, API, ASME, and ANSI provide comprehensive guidelines on quality and safety. Therefore, selecting valves certified by reputable organizations ensures adherence to the highest industry benchmarks, a critical consideration for projects involving stringent regulatory compliance. Trustworthiness, often gained through verifiable testimonials and case studies, is critical while making purchasing decisions. Leading manufacturers and suppliers not only provide extensive documentation on their valve's performance but also allow potential buyers to access case studies detailing successful implementations. This transparency builds confidence, ensuring that clients can make informed decisions backed by real-world performance data. In summary, the vulcanized seat flange butterfly valve represents a significant advancement in valve technology tailored to demanding industrial applications. Its strength lies in its ability to combine flexibility in operations with seal integrity, backed by strategic material choice and compliance with international standards. By engaging with experts and leveraging industry insights, businesses can enhance their liquid handling systems' efficiency, ensuring operational safety and longevity. As industries continue to evolve, staying informed on technological advancements, material science innovations, and regulatory changes will be key to leveraging the full potential of these indispensable components.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025