Pro . 31, 2024 05:16 Back to list

grooved end butterfly valve

Understanding Grooved End Butterfly Valves A Comprehensive Overview

Butterfly valves play a crucial role in various industries by controlling fluid flow within pipes. Among the different types available, the grooved end butterfly valve stands out due to its ease of installation and versatility. This article provides an in-depth look at grooved end butterfly valves, discussing their design, applications, advantages, and maintenance.

What is a Grooved End Butterfly Valve?

A grooved end butterfly valve is a type of valve that features a disc, or butterfly, which rotates to open or close the valve, thereby regulating fluid flow. The unique characteristic of the grooved end is the groove design on the valve's ends that allows for a quick and efficient connection to the piping system through the use of couplings. This design eliminates the need for welding and provides a reliable, leak-proof seal.

Design Features

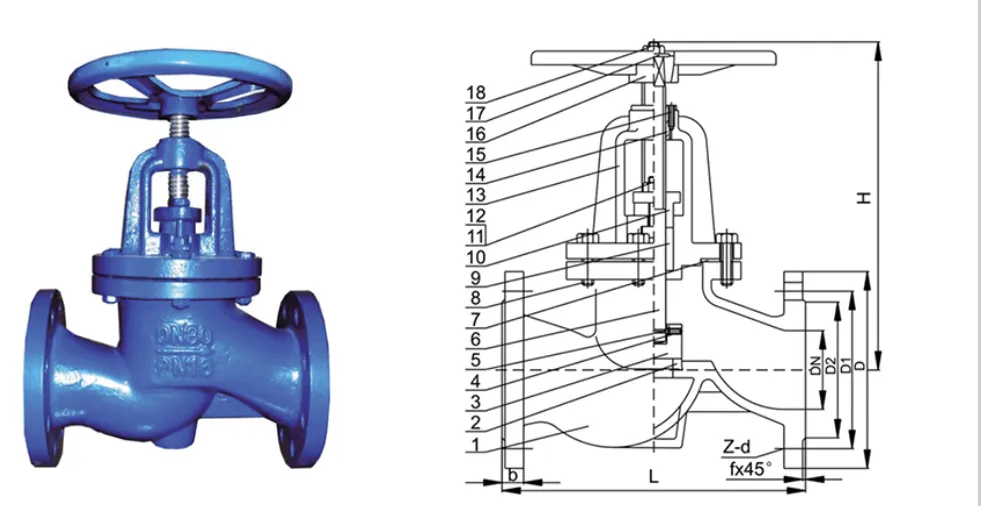

The grooved end butterfly valve typically consists of the following components

1. Body The body of the valve is usually made of durable materials such as cast iron, stainless steel, or PVC, which ensure longevity and resistance to corrosion.

2. Disc The disc is pivoted on a stainless steel shaft, which allows for smooth rotation. Depending on the design, the disc can be made from various materials to suit specific applications.

3. Seals Sealing materials can include elastomers such as Nitrile (Buna-N), EPDM, or PTFE, providing an effective barrier against leaks.

4. Actuators Depending on the application, butterfly valves can be operated manually or automatically through electric or pneumatic actuators.

5. Grooved Ends The distinct grooved ends ensure a secure fit with the pipe, using mechanical couplings that allow for easy installation and disassembly.

Applications

Grooved end butterfly valves are versatile and used in various sectors, including

- Water Supply and Distribution These valves help control water flow in municipal systems, ensuring efficient distribution.

- HVAC Systems In heating, ventilation, and air conditioning systems, butterfly valves regulate the flow of air or liquids.

- Industrial Processes Factories use these valves for managing flow in chemical, petrochemical, and food processing systems

.grooved end butterfly valve

- Fire Protection Systems In fire suppression systems, these valves play a key role in controlling the water supply.

Advantages of Grooved End Butterfly Valves

1. Ease of Installation The grooved design allows for quick assembly with minimal tools, reducing labor costs and installation time.

2. Compact Design These valves are lightweight and compact, making them ideal for applications where space is limited.

3. Cost-Effective The efficient installation reduces overall costs, and their durable materials ensure long service life, leading to lower maintenance expenses.

4. Versatile Application With various materials and sizes available, grooved end butterfly valves can be tailored for a wide range of applications and environments.

5. Reliable Performance The robust design provides a dependable seal, minimizing the chances of leakage and the resulting environmental impact.

Maintenance Tips

To ensure the longevity of grooved end butterfly valves, regular maintenance is essential

1. Visual Inspections Periodically check the valve for signs of corrosion, wear, or damage.

2. Lubrication Regularly lubricate the shaft and actuator to ensure smooth operation.

3. Seal Checks Inspect the seals for any signs of wear or degradation that could lead to leaks.

4. Operational Tests Perform operational tests to confirm that the valve opens and closes smoothly and fully.

5. Professional Servicing Engage professional services for detailed maintenance or when replacement of components is necessary.

Conclusion

In summary, grooved end butterfly valves are an essential part of fluid control systems across numerous industries. Their design enhances ease of installation, ensures reliable performance, and offers versatility for various applications. Regular maintenance of these valves will help maximize their service life and operate efficiently. As industries continue to seek efficient ways to manage fluid flow, the grooved end butterfly valve will undoubtedly remain a popular choice.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025