Pro . 25, 2024 11:25 Back to list

flanged butterfly valve

Flanged Butterfly Valves An Overview

Flanged butterfly valves are integral components in various industrial applications, serving primarily as a means of regulating and isolating flow within piping systems. These valves are particularly favored for their simplicity, lightweight construction, and versatility, making them suitable for a wide range of fluids, including water, gas, and even some corrosive chemicals.

Design and Construction

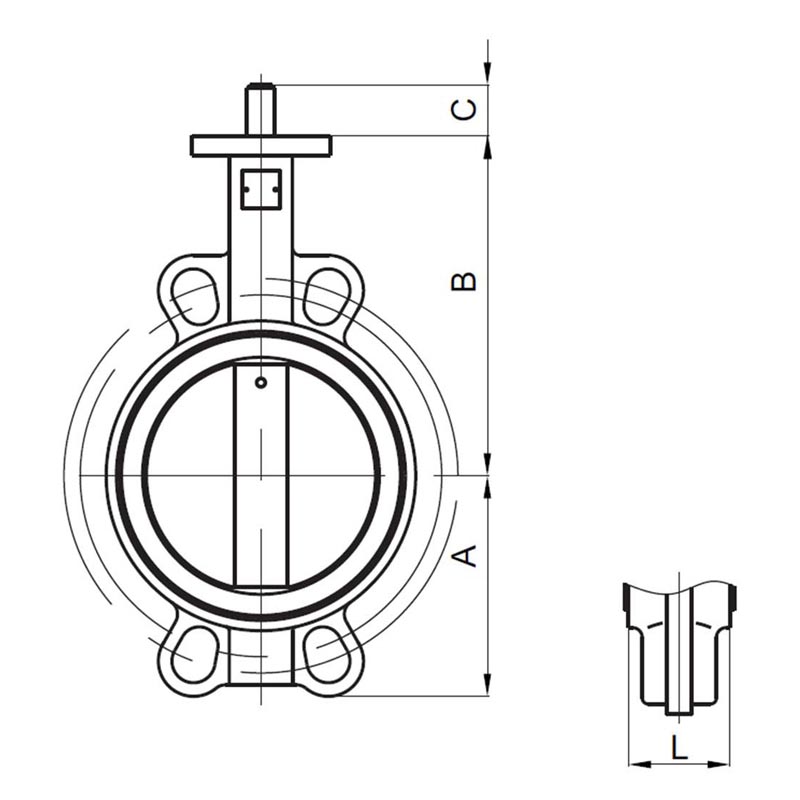

The design of a flanged butterfly valve consists of a circular disc or ‘butterfly’ that rotates around a valve shaft. Unlike traditional gate valves, the butterfly valve is engineered to allow for quick opening and closing, which can be achieved by rotating the disc a quarter turn (90 degrees). This mechanism offers significant advantages in terms of speed and efficiency, which is crucial in many operational settings.

The ‘flanged’ aspect refers to the valve’s connection method. Flanged valves feature raised rims or ‘flanges’ at the ends, which allow for easy bolting to the corresponding flanges of piping systems. This secure connection is essential for maintaining system integrity under varying pressures, preventing leaks that can lead to inefficiencies and safety hazards. Flanged butterfly valves can be made from a variety of materials, including cast iron, stainless steel, and plastic, each chosen based on the specific requirements of the application, such as temperature and corrosion resistance.

Operation Mechanism

The operation of a flanged butterfly valve is relatively straightforward. When the valve is opened, the disc is oriented parallel to the flow of fluid, minimizing resistance and allowing for maximum flow capacity. Conversely, when the valve is closed, the disc is perpendicular to the flow, effectively blocking the passage. This design not only contributes to efficient flow control but also allows for a compact installation, which is especially beneficial in environments with limited space.

Flanged butterfly valves can be operated manually, using a handle or lever, or automatically, through electric or pneumatic actuators. The choice of actuation depends on the level of automation required in the process and the specific operational conditions of the system.

flanged butterfly valve

Applications

These valves are commonly used in various sectors, including water treatment, food and beverage, HVAC systems, and chemical processing. In water treatment plants, for instance, flanged butterfly valves are utilized for isolation and throttling applications, ensuring that water flows only where it is needed while also providing a means to quickly shut off flow in case of emergencies.

In the food and beverage industry, hygiene and efficiency are paramount, making the easy cleaning and smooth operation of flanged butterfly valves particularly advantageous. In chemical processing, resistance to corrosive substances and robust construction are critical factors that flanged butterfly valves can offer.

Advantages

The benefits of flanged butterfly valves are numerous. Their lightweight design simplifies installation and maintenance, and their quick operation reduces downtime in critical processes. Compared to other valve types, butterfly valves also tend to be less expensive and require less space, making them an attractive option for many industrial applications.

Furthermore, with advancements in materials and manufacturing techniques, modern flanged butterfly valves can withstand extreme temperatures and pressures, enhancing their reliability and lifespan.

Conclusion

In conclusion, flanged butterfly valves are essential components in modern piping systems due to their efficient flow control capabilities, ease of installation, and versatility across various industries. Their robust design and operational advantages render them an ideal choice for both simple and complex applications. As industries continue to evolve, the importance of reliable and efficient flow control solutions like flanged butterfly valves will only increase, making them a ubiquitous fixture in the engineering landscape.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025