Pro . 04, 2024 04:36 Back to list

ductile valve

Understanding Ductile Valves A Key Component in Modern Engineering

In the engineering and manufacturing industries, the importance of reliability and durability cannot be overstated. Among the tools that meet these criteria are ductile valves, which have gained prominence due to their exceptional performance and resilience in various applications. This article aims to explore the concept of ductile valves, their characteristics, the materials used in their construction, and their significance in different industries.

What is a Ductile Valve?

A ductile valve is a type of valve designed to control the flow of liquids, gases, or slurries within a system. The term ductile refers to the material’s ability to deform under tensile stress without losing its toughness, which allows the valve to withstand significant pressure and stress without breaking. This property is crucial in applications where the valve may face extreme conditions.

Characteristics of Ductile Valves

1. Durability Ductile valves are designed to withstand harsh environments, making them an ideal choice for industrial applications. Their construction materials, often including ductile iron, impart resistance to wear and corrosion.

2. Flexibility Due to their ductility, these valves can tolerate a certain degree of flexing during operation. This attribute helps in applications where there might be vibrations or thermal expansions, ensuring longer service life.

3. Strength Ductile valves are known for their high strength-to-weight ratio. This feature not only makes them lightweight and easy to install but also provides the strength required for demanding applications.

4. Sealing Efficiency Many ductile valves are designed with advanced sealing technologies that ensure minimal leakage. This is particularly important in industries like oil and gas, where even small leaks can lead to significant financial and environmental consequences.

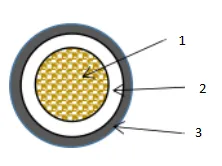

Materials Used in Ductile Valves

ductile valve

The most common material used for ductile valves is ductile iron, which is known for its excellent mechanical properties

. Ductile iron valves are often coated with protective layers to enhance corrosion resistance. Additionally, various alloys and composite materials may be employed depending on the specific requirements of the application, such as temperature resistance, chemical compatibility, and pressure ratings.The choice of material is influenced by factors such as the type of fluid being transported, the environmental conditions, and regulatory standards that must be adhered to. For instance, in the water treatment industry, ductile valves may need to be compliant with health and safety regulations, requiring special coatings and materials to prevent contamination.

Applications of Ductile Valves

Ductile valves find applications across numerous industries due to their versatility and reliability. Here are a few notable examples

1. Water and Wastewater Management In municipal water supply systems and wastewater treatment plants, ductile valves control the flow of water and effluents. Their ability to withstand corrosive environments makes them suitable for these applications.

2. Oil and Gas The oil and gas industry relies heavily on ductile valves to manage the flow of hydrocarbons. Their strength and sealing capabilities are crucial in preventing leaks and ensuring safety in high-pressure systems.

3. Chemical Processing Ductile valves are widely used in chemical plants for their resistance to various chemicals and high temperatures. They play a vital role in process control and safety.

4. Heating, Ventilation, and Air Conditioning (HVAC) In HVAC systems, ductile valves help regulate airflow and maintain system efficiency, contributing to energy savings and improved indoor air quality.

Conclusion

Ductile valves are indispensable components in a myriad of systems across different industries. Their unique properties—strength, durability, flexibility, and sealing efficiency—make them suitable for challenging applications. As technological advancements continue to influence the manufacturing process and material science, the development of even more efficient and reliable ductile valves will likely shape the future of engineering solutions. The ongoing demand for high-performance materials in various sectors underscores the significance of ductile valves in maintaining operational efficiency and safety in industrial processes. As industries evolve, embracing innovations in ductile valve technology will remain a priority for engineers and manufacturers alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025