Lis . 12, 2024 21:30 Back to list

di gate valve

The Functionality and Importance of Diaphragm Gate Valves

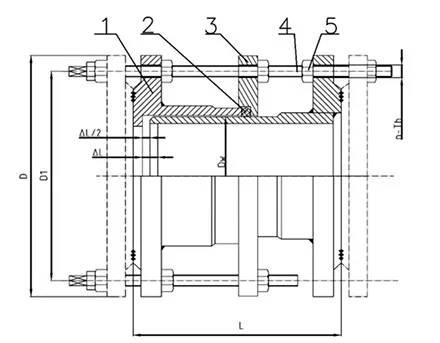

Diaphragm gate valves are essential components in various industrial applications, renowned for their unique design and functionality. Unlike traditional gate valves that use a wedge-type gate, diaphragm gate valves utilize a flexible diaphragm to control the flow of fluids effectively. This unique mechanism provides several advantages that make them suitable for specific applications, particularly in the chemical, pharmaceutical, and food processing industries.

One of the primary functions of a diaphragm gate valve is to provide an effective seal. The diaphragm, typically made from elastomeric materials, creates a barrier that prevents leakage. This capability is particularly crucial in processes involving hazardous or corrosive fluids, where even minimal leakage can pose significant safety risks. The design of the valve ensures that the diaphragm remains in contact with the body of the valve, maintaining a tight seal even under varying pressure and temperature conditions.

The Functionality and Importance of Diaphragm Gate Valves

Maintenance is another area where diaphragm gate valves excel. Traditional valves often require more complex maintenance routines due to their intricate mechanical components. In contrast, diaphragm valves are typically simpler in their construction. The flexible diaphragm can be replaced with minimal downtime, allowing for efficient maintenance without extensive disassembly. This feature is especially important in industries where uptime is critical. The reduced maintenance needs translate to lower operational costs and improved productivity.

di gate valve

The operation of diaphragm gate valves is also noteworthy for its user-friendliness. These valves can be easily actuated manually or automatically, providing operators with the flexibility to integrate them into existing systems with ease. The straightforward mechanism reduces the risk of operational errors, further enhancing the safety and reliability of the processes they control.

Moreover, diaphragm gate valves are not only effective in controlling flow but also in handling pressure variations within a system. They can be fully closed without the risk of water hammer, a phenomenon that occurs when a fluid in motion is forced to stop or change direction suddenly, potentially causing damage. This feature makes diaphragm gates preferable in applications where pressure surges are a concern.

When selecting a diaphragm gate valve, several factors should be considered, including the type of fluid, temperature, pressure ratings, and the specific application's requirements. Each application may call for different materials and designs; for instance, materials must be chosen to withstand chemical corrosion in particular environments. Therefore, understanding the operating conditions is critical to ensuring a long service life for the valve.

In conclusion, diaphragm gate valves play a vital role in various industries, thanks to their unique design, effective sealing capabilities, and ease of maintenance. Their versatility and reliability make them the preferred choice for applications ranging from chemical processing to food manufacturing. As industries continue to evolve and demand more efficient and safer solutions, diaphragm gate valves will undoubtedly remain an integral component of fluid control systems worldwide. By harnessing the benefits of these valves, companies can ensure operational efficiency, safety, and compliance with stringent industry standards.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025